Serpentix Conveyor Corporation, Inc. products

Conveyor

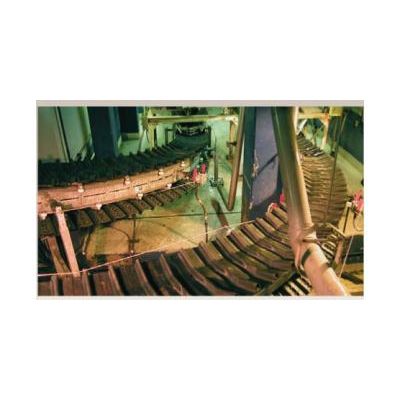

Serpentix - Sludge Conveyor

The Model H is the heaviest duty Serpentix designed to convey up to 400 tons per hour at maximum speeds on slightly more than 100 feet per minute over distances up to 500 feet. Belt widths for Model H are 20". 26". and 32".

Serpentix Pathwinder - Screening Conveyor

Pathwinder conveying systems solve difficult bulk handling problems encountered in municipal and industrial applications. Unique design parameters allow the conveyor to follow horizontal, vertical, and helical paths. These diverse path capabilities provide an alternative when adapting a conveyor to an existing facility where interfacing with more permanently positioned equipment is required.

Serpentix Palhwinder - FlexEnd Conveying Systems

The Serpentix Pathwinder FlexEnd option enables the Pathwinder conveyor to distribute material over a twelve-foot arc. Controlled with a pneumatic cylinder, a control valve, and a manual control stick, the Flextrack makes it possible to evenly deposit material over a given area. No longer will plant personnel inch a track forward to completely load a trailer.

Serpentix - Flight Distribution Conveyor (FD)

The Serpentix Flight Distribution (FD) Conveyor, used in conjunction with our standard conveyors, or as a stand-alone unit, allows for material to be distributed over a large area with multiple exit points. This is the ideal solution for distributing waste material to material to multiple bins or truck beds, and allows the end user to simply open or close the exit points as needed by way of the pneumatic slide-gate system.

Automation

Serpentix - Control Panels

Serpentix Automation provides high quality OEM control panels by experienced designers and highly skilled craftsmen. Whether you need a one-off panel, or several hundred, we can help. Regardless if your project includes a standard or complex design, we will create a clean, well organized, functional panel that is correctly assembled with the proper UL stickers. Our OEM panels are built cost-effectively to meet customer`s expectations and budget. We specialize in designing and building electrical control panels for customers who have OEM machines. Your panel is value-engineered to our high standards of quality and reliability, and designed to minimize production costs and time. We use components from names customers trust, like Allen-Bradley. Siemens, GE, and SquareD to produce high quality control panels.

Fabrication

Serpentix Cincinnati - Fiber Laser System

Serpentix uses a Cincinnati CL-940 Fiber Laser System which offers a high speed cutting on thinner materials and lower operation costs. Having all the features needed to cut parts fast and accurately in one machine gives us the ultimate flexibility to build the best solutions that meet your needs. We have the capability of cutting mild steel, stainless steel, and aluminum up to 1/2″ thick. Our fabrication processes include: bending, drawing, folding, forming, laser cutting, plating, shearing, and welding.

Serpentix Cincinnati - Maxform Press Brake

To produce-high quality products, we use Maxform press brake which is the most advanced press brake that produces maximum productivity through fast programming, fast setup, and fast cycle speeds. Our press brake comes with a touchscreen computer control that allows our engineers to produce detailed work that meets your specifications. We can bend the following materials; mild steel, stainless steel, and aluminum up to 1/2″. We are also capable of bending custom angles, custom channels, and Z shapes. Our fabrication processes include: bending, drawing, folding, forming, laser cutting, plating, shearing, and welding.

Serpentix - Metal Finishing Machines

We use a number of metal finishing machines to meet the needs of our customers, who have projects that require a smooth, clean, and soft metal. If your project requires any metal finishing, then Serpentix is your one-stop-shop.