- Home

- Companies

- SH Sulphtec GmbH

- Products

SH Sulphtec GmbH products

Biogas Desulphurization

Sulphtec - Model SH-Classic - Biological Trickling Filter

The biological desulphurization with a classic biological trickling filter is a proven method for many years to remove high to very high H2S (hydrogen sulphide) content from bio, sewer and landfill gas. The problem of many biological desulphurization plants is the blockage of the filling material which have to be painstakingly removed and renewed. This can´t happening with the „Classic“ line from SH SULPHTEC due to some major differences from rival systems. Therefore, blockage is technically nearly impossible.

SH SulphPur - Biological Trickling Filter

The advantage of the biological trickling filter SH SulphPur® from SH SULPHTEC is the extremely low water and energy consumption. SH SulphPur® is especially suitable for biomethane plants due to a very low oxygen (O2) demand of 0.3 to 0.5 Vol.%. Therefore, less than 0.3 Vol.% oxygen is reached in the outlet of the SulphPur® plant. A blockage is technically impossible regardless that the plant converts 80 % of the hydrogen sulfide (H2S) to elementary sulfur.

SH-Sulphtec - Model S-KAT - Mini Biological Trickling Filter

The SH S-Kat is a round PE container (ᴓ1200 mm) with mineral filling medium on which the bacterica can grow due to its huge inner and outer surface, and convert the H2S into Sulphate. This Sulphate will be derived from the reactor with the process water through a siphon. The operation costs of the SH S-KAT are extremely low with less than 50,00 € per year and can also be easily installed in an existing system. Another big advantage is the lack of a gas drying system with a heat exchanger and an expensive air conditioner, because the biogas doesn´t require drying. The SH S-KAT is also used to reduce the costs of activated carbon or to waive iron salts.

Exhaust Air Purification

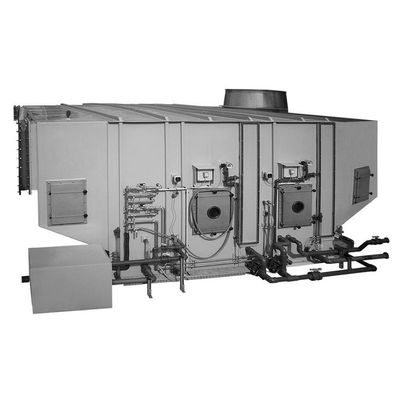

SH-Sulphtec - Model A-Clean - Biological Surface Filter

With the help of microorganisms, the SH surface filter decomposes pollutants in the exhaust air. Both acquisition and operating costs are low, and maintenance is also minimal. The pollutant substances in the exhaust air are absorbed by the surface of the biological filter material and the microorganisms (which live on the material) gain access. The microorganisms use the air pollutants as a source of nutrients and energy to build up their own biomass (so called biological oxidization). This natural process of biological exhaust air purification is optimally realized with the SH A-CLEAN biological filter.

SH Sulphtec - Model C-Wash - Chemical Ammonia and Hydrogen Sulphide Scrubber

With high concentrations of ammonia (NH3), hydrogen sulphide (H2S) or other pollutants, the exhaust air needs to be pre-treated before the gas is sent to the surface or container filter.The SH C-Wash from SH SULPHTEC is used for this purpose.