Shandong Yanggu Dragon New Material Co.,Ltd. products

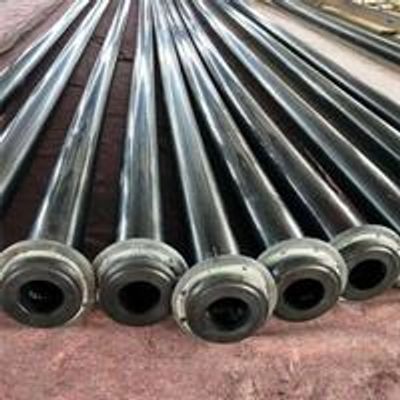

UHMWPE Pipes

Ultra-high Molecular Weight Polyethylene Pipe

Ultra-high molecular weight polyethylene (UHMWPE) is a kind of engineering thermoplastics with more than 3 million viscosity-average molecular weight. It differs from PE standard grades in its very high degree of polymerization. Ultra-high molecular weight polyethylene pipe has superior performance over conventional HDPE pipe. The nominal pressure rating of UHMWPE pipes etc. is from 0.6 MPa to 2.0 MPa and UHMWPE composite pipe can reach 6.4 MPa.

Ultra-high Molecular Weight Polyethylene Pipe

Ultra-high molecular weight polyethylene (UHMWPE) is a kind of engineering thermoplastics with more than 3 million viscosity-average molecular weight. It differs from PE standard grades in its very high degree of polymerization. Ultra-high molecular weight polyethylene pipe has superior performance over conventional HDPE pipe such as very high wear resistance, impact resistance, intrinsically self-lubricating, anti-adhesion,low temperature resistance and excellent chemical resistance.

Conveyor Roller

Item : Customized uhmwpe machined parts. Color : White,black,blue,etc.. Material : uhmwpe. Size : OEM with drawings. Advantage : Smallest friction coefficient,good wear resistance, self0lubrication.

Food Grade UHMWPE Pipe

Ultra-high molecular weight polyethylene (UHMWPE) is a kind of engineering thermoplastics with more than 3 million viscosity-average molecular weight. It differs from PE standard grades in its very high degree of polymerization. Ultra-high molecular weight polyethylene pipe has superior performance over conventional HDPE pipe such as very high wear resistance, impact resistance, intrinsically self-lubricating, anti-adhesion, low temperature resistance and excellent chemical resistance. UHMWPE pipe is more rigid than LDPE and HDPE, and has better abrasion resistance than PTFE.

Mining Pipe

Ultra High Molecular Weight Polyethylene (UHMWPE) is a linear polyethylene with molecular weight of over2.5X 10^6 which is approximately ten times that of high molecular weight high density polyethylene resins. The extremely high molecular weight of this resin offers superior performance of UHMWPE to any other thermal engineering plastic

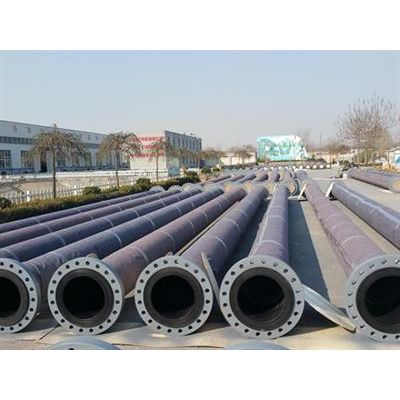

Lined Steel Pipes

Lined Steel Pipe

In order to meet the demand of long distance, high pressure, high wear resistance, anti-adhesion, etc, our company develop and produce DN63mm to DN630mm composite pipe, our UHMWPE pipe can composite with sprial welding pipe, high quality seamless pipe, etc. With the lining thickness of 8mm -20mm, the UHMWPE steel composite pipe not only make full use of the excellent properties of UHMWPE,it also can adapt high pressure, enhance the long distance fieldwork transmission, effectively prevent external destruction,filling the domestic gap in the field of composite pipe, expand the application area Pressure: 5MPa-32MPa.

Steel Composite Pipe

UHMWPE composite pipe is made of UHMWPE pipe and carbon steel pipe. Its outer layer is the steel pipe with flange as the pressure standing protective layer, UHMWPE pipe is lined inside as wear layer, anti corrosive pipe with extremely smooth surface. The inner UHMWPE pipe is extended out of the outer layer of carbon steel pipe and flanged as connection of pipe.

dragon uhmwpe - mineral ore slurry pipeline made from UHMWPE

UHMWPE, as a material with high wear resistance and anti corrosion property, is used as lined of steel pipe. The combination is called UHMWPE lined steel pipe, it is used for transport highly abrasive pulp, usually we call it mineral slurry pipeline.PE Floaters

Dredging Floater

The hull of MDPE FLOATER is made from medium density polyethylene material with excellent flexibility, filled with high strength polyurethane foam inside. With reasonable structure and good performance, the MDPE floater becomes the ideal substitution of the traditional steel floater for the floating dredging pipes.

UHMWPE Rods

Ultra-high Molecular Weight Polyethylene Rods

Ultra-high molecular weight polyethylene (UHMWPE) is a kind of engineering thermoplastics with more than 3 million viscosity-average molecular weight. It differs from PE standard grades in its very high degree of polymerization. Ultra-high molecular weight polyethylene pipe has superior performance over conventional HDPE pipe such as very high wear resistance, impact resistance, intrinsically self-lubricating, anti-adhesion, low temperature resistance and excellent chemical resistance.