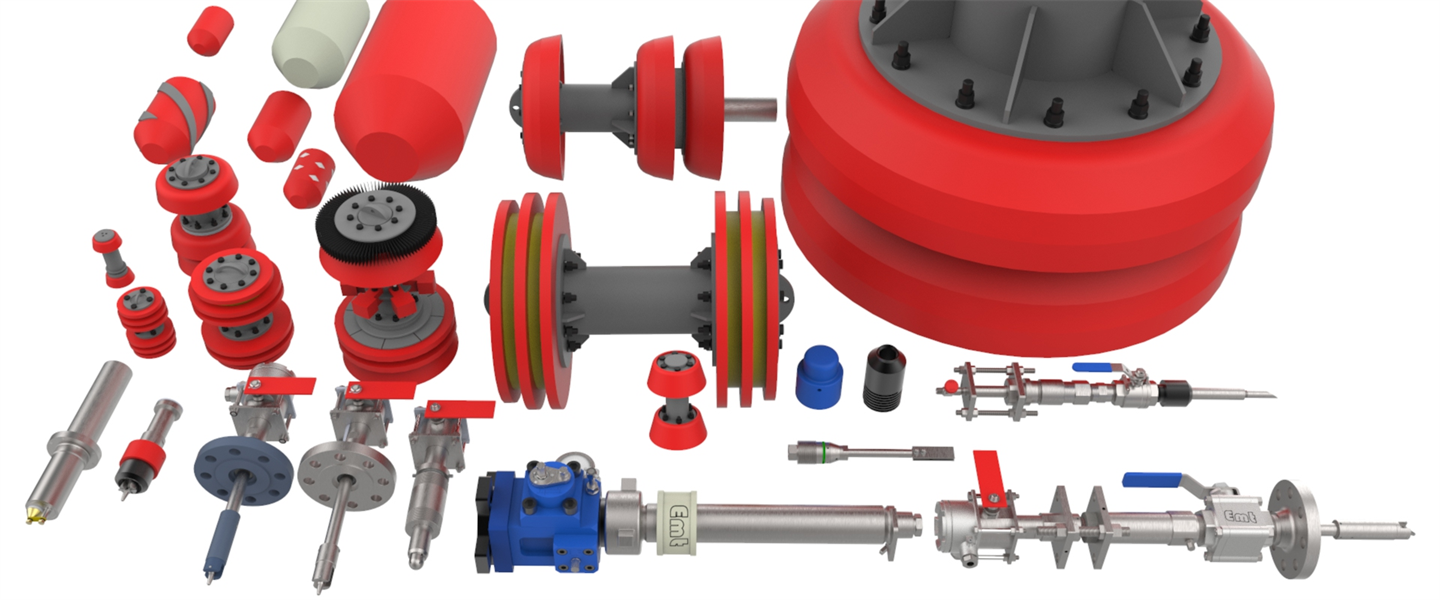

Shenyang EMT Pigging Technology Co., Ltd. products

Pipeline Cleaning Pig

It is applied to pigging before production, cleaning the stones, wood bars and other matters left in the pipeline.

Corrosion Coupon & Corrosion Probe

Corrosion Text & Sampling System. Corrosion Coupon: Corrosion coupon assembly is a corrosion detection device and is one of the methods for the study of corrosion and its effects. Corrosion Coupon is relatively small, easily inserted and retrieved by or corrosion coupon with built-in retriever. Using Corrosion Coupon Assembly is an economical means of determining cause and effect of corrosion. The types of Corrosion Coupon are strip and disc, with corresponding Strip Coupon Holders and Disc Coupon Holders.

Chemical Injection Quill

The chemical injector and sampler are the end devices of the chemical injection system or the piping medium sampling system.Periodically injecting chemical inhibitor into the pipeline is the most practical way for minimizing or controlling corrosion, which requires chemical injectors. EMT Injection System for easy, reliable access, inhibitors can be injected under operating pressure with safety.The chemical injector has many types of nozzles.The sampler is approximately the same as the injector.

Pipeline Pig - Disc Pig

EMT - Cleaning Bi-Di Disc Pig for Effective Pipeline Cleaning

The Cleaning Bi-Di Disc Pig is a robust and efficient tool for pipeline cleaning applications, designed and manufactured by Shenyang EMT Pigging Technology Co., Ltd. Made from high-quality polyurethane, this pig boasts superior wear resistance and tear strength, making it highly durable and suitable for demanding pipeline environments. Its unique design features a steel framework with optional sealed cups or steel brushes, which allow it to perform dual functions of water absorption and cleaning simultaneously. This pig is versatile and can handle diverse tasks such as new pipeline pigging, rust removal, water resistance, drainage, and media isolation. Over the years, it has been extensively used in the Daqing and Liaohe oil fields, known for its consistent performance and reliability. Key technical metrics include a shore hardness of 83 (GB/T531.1-2008), DIN abrasion of 21 mm³ (GB/T53516-1987), and tensile strength of 51.2 MPa (GB/T528-2009). The product's excellent sealing performance, accurate location and tracking capabilities, and low rate of false positives further enhance its efficiency. Available in various materials such as Polyurethane, Viton, Neoprene, and Nitrile butadiene, the Cleaning Bi-Di Disc Pig is designed to extend its operational lifespan while reducing maintenance costs.EMT - Magnetic Brush Bi-Di Disc Sealing Pig for Pipeline Cleaning

The Magnetic Brush Bi-Di Disc Sealing Pig is designed for efficient pipeline cleaning in industries such as food hygiene and petroleum. It features a robust steel framework complemented by either sealed cups or steel brushes. Equipped with magnets for precise positioning and control, this pig can be cleaned and tracked within a closed system. The modular design minimizes the need for diverse spare parts, significantly reducing product losses. It includes 2 to 4 sealed cups or steel brushes, engineered from materials like Polyurethane, Viton, Neoprene, and Nitrile butadiene. Suitable for pipelines with a maximum 90-degree bending and bending radius of 3.0 xD, it is highly effective for pipeline pigging, drainage, water resistance, and media isolation. The product demonstrates superior wear resistance, passing ability, and cleaning performance, with specifications complying with standards such as GB/T531.1-2008, GB/T53516-1987, and GB/T528-2009. It is a trusted choice for renowned oil fields like Daqing and Liaohe.Pig Signaller - Flange Connection Pig Signaller

EMT - Removable Pig Signaller With Flange

The Removable Pig Signaller With Flange is designed for monitoring the movement of pipeline pigs through various types of pipelines. This device can be chosen for either bi-directional or uni-directional pigging processes according to user requirements. It is positioned at critical points like pig launching and receiving stations to provide a reliable indication of pig passage. Key features include a withstand pressure of 6.4MPa and adaptability to pipeline diameters over 150mm. It operates efficiently within temperature ranges of 0°C to 80°C. Additional functionalities include optional remote control signaling, and it supports multiple remote interface types such as 1/2NPT (F), 3/4 NPT (F), and M20 * 1.5 (F). The Pig Signaller with flange is constructed with a mechanical contact type structure, ensuring a simple, low-cost, yet intuitive and reliable operation. It is useful for long-distance pigging processes, sweeping operations, and provides precise passage time notifications to aid operators during pipeline operations. The product is ISO9001, ISO45001, and ISO14001 certified which underscores its compliance with international standards.EMT - Bidirectional Flange Pig Signaler

The Bidirectional Flange Pig Signaler is an integral tool for the pipeline cleaning process. It is securely installed over the pipeline to detect the passage of pigs at specified points, aiding in the operational control during pigging activities. This device offers secondary indication mechanisms such as lights, points, sounds, or special clocks to alert operators. Designed to ensure accurate tracking of pipeline pigs, it is installed at both launching and receiving stations, as well as at strategic points along the pipeline to confirm pig movement bidirectionally. Available in manual reset flag, manual reset flag with electrical switch output, and digital display combined with electrical switch output variants, it features three mounting types: 2″ flange connection, welded nipple, and welded base-NPT nipple connection. Capable of handling pressures from ANSI 150# to ANSI 2500# and working temperatures from -20ºC to +120ºC, it includes a trigger mechanism without dynamic seals to prevent leaks and ensure flexibility. Compatibility with various pig types and minimal maintenance requirements make it suitable for a range of pigging applications.Foam Pig

Foam Pig

Starting pressure: 0.02 MPa. Density: 35 kg/m3-200 kg/m3. Withstand pressure: 7 MPa. Stretch rate: 320%. Compression ratio: 60. Flex life: 50,000 times. Attrition rate: 4 mm/100 km. Operating distance: 50 km~150 km. Operating temperature: -30°C~100°C.

Foam Pig

Starting pressure: 0.03 MPa. Density: 35 kg/m3-200 kg/m3. Withstand pressure: 7 MPa. Stretch rate: 320%. Compression ratio: 40. Flex life: 50,000 times. Attrition rate: 2 mm/100 km. Operating distance: 50 km~150 km. Operating temperature: -30°C~100°C.

Foam Pig

Starting pressure: 0.02 MPa. Density: 35 kg/m3-200 kg/m3. Withstand pressure: 7 MPa. Stretch rate: 320%. Compression ratio: 50. Flex life: 50,000 times. Attrition rate: 2 mm/100 km. Operating distance: 100 km~300 km. Operating temperature: -30°C~100°C.