Shree Biocare Solution Pvt Ltd. products

Laboratory Autoclaveble Fermentor & Bioreactor

Fully automatic PLC controlled /Microprocessors controlled Capacity - 1 L to 15 L Glass Jcektted / S.S. / Glass with SS Jacked Attach with PC and get the print out as per batch. SB offer controlled parameter such -agitation,aeration, ph, temp, antifoam,DO2, Total Bio Mass, Co2 etc... Ideal for high yield production of bacteria, yeast, fungi, cell cultural, enzyme, primary / secondary metabolism and many more ... SB Fermentor/Bio reactor meets Batch / Fed Batch / Continues Batch mode. Aerobic & anaerobic.

Laboratory In-Situ Fermentor & Bioreactor

SB fermenter/Bioreactor are PLC based controller with large touch screen module. Attach with PC (SCADA) Operated by software & data as per 21 CFR part 11. SB offer controlled parameter such –agitation,aeration, ph, temp, antifoam,DO2, Total Bio Mass, Co2 etc... SB fermenter/Bioreactor offer glass vessel with Bottom S. S. Jacketed, complete / S. S. Vessel. Capacity - 1 L to 10 L Ideal for high yield production of bacteria, yeast, fungi, cell cultural, enzyme, primary / secondary metabolism and many more …. SB Fermentor/Bio reactor meets Batch / Fed Batch / Continues Batch mode. Aerobic & anaerobic.

Pilot Scale Fermentor & Bioreactor

Skid Mounted volumes capacity 10 liters to 1000 liters. Top Driven / Bottom Driven. Jacketed pressure vessel mode of stainless steel. SB fermentor / Bioreactor are PLC based controller with large touch screen module. Attach with PC (SCADA) Operated by software & data as per 21 CFR part 11. SB offer controlled parameter such – agitation, aeration, ph, temp, antifoam, DO2 ,Total Bio Mass, Co2, Exit Gas etc... Ideal for high yield production of bacteria, yeast, fungi, cell cultural, enzyme, primary / secondary metabolism and many more ....

Bio Inactive System

Bio inactive system is a product line that caters to inactivation of biowaste generated at every step of the biopharmaceutical production. This includes waste generated from fermentors , autoclaves, sewers, etc, which could be potential threat to environment if not handled carefully before releasing it to the effluent stream. Bioinactive system is designed to inactivate these effluents using heat treatment mechanism. Batch bioinactive system Flexible range Skid mounted. Configuration to suit space restrictions. Design conforms to ASME BPE and GAMP 5 guidelines. PLC control system with SCADA. 100% redundancy for safety. 100 L to 500 L.

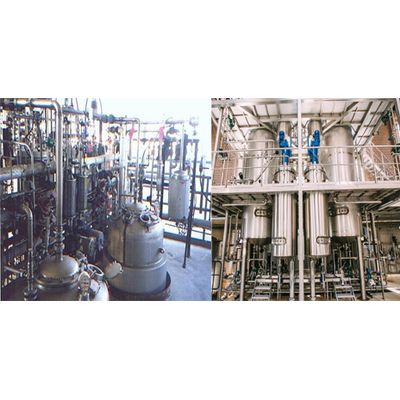

Production Scale Fermentor & Bioreactor

Capacity – 1000 L to 35000 L. TOP/Bottom Drive system. SB Fermentor/Bioreactor meets Batch / Fed Batch / Continous Batch mode. Areobic & anaerobic.. SB fermenter/Bioreactor are PLC based controller with large touch screen module. Attach with PC (SCADA) Operated by software & data as per 21 CFR part 11. SB offer controlled parameter such – agitation, aeration, ph, temp, antifoam, DO2 Total Bio Mass, Co2 etc... Ideal for high yield production of bacteria, yeast, fungi, cell cultural, enzyme, primary / secondary metabolism and many more …..