Sigma S.A products

Waste Management

Technological lines

The business activities of SIGMA cover the design, manufacture, assembly and commissioning of technological lines for following types of waste: municipal mixed waste, municipal waste from selective collection, post-construction waste, industrial waste (paper, cardboard, metal, glass). Our lines allow the segregation of materials according to the size of the material, type, shape and color. Each technological line is designed and tailored to the individual requirements of the customer, with appropriately selected machines and equipment efficiency, number of separated material and structure of waste.

Control, Automation And Visualization Systems

SIGMA S.A. designs and manufactures control, automation and visualization systems for technological processes, based on components from reliable global manufacturers, such as SIEMENS, SEW, LENZE, NORD. Our systems meet most strict market requirements resulting from introduction of new regulations and general global technological advancement. Our designed systems enable the remote control, diagnosis and adjustment of operating parameters in individual devices.

Waste Management - Transport Systems

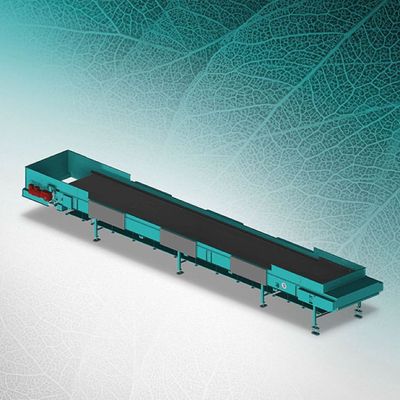

Belt Conveyor

Applied at segregation lines as sorting, bunker or channel feeders for input material transportation at various stage of sorting process. In first stage of sorting process, they transport input material of heavy bulk load e.g. mixed waste fraction, sieved mineral fractions, up to light fractions segregated in subsequent stages of sorting, such as paper, plastic, foil.

Chain Conveyor Belt

Chain conveyor belts are designed to transport various materials, including mixed municipal waste of heavy bulk load, as well as segregated light fractions like paper, plastic, foil. Due to its construction, chain conveyor belts can be bended in rising (incline) position what allows to transport input material to high located points, even in halls/buildings of limited spatial structure.

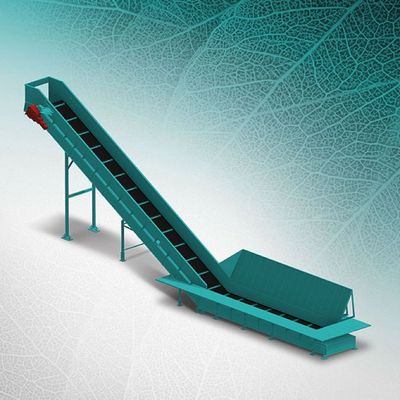

Incline Belt Conveyor

Incline belt conveyors are applied for transport of input material to significant height, at incline (rising) angle above 20° during various stage of sorting process. In first stage of sorting process, they transport input material of heavy bulk load e.g. mixed waste fraction, sieved mineral fractions, up to light fractions segregated in subsequent stages of sorting, such as paper, plastic, foil.

Material Handling - Cable Type Industrial Manipulators

Model SIGMA ML - Cable Type Manipulator

The SIGMA ML cable type manipulator with the individually designed and manufactured gripper is used in applications related to palletization or depalletization, as well as handling of loads in production lines. Designed for any industry where increase of work efficiency is required, from the wood industry to the food industry.

SIGMA - Model ML-Z - Industrial Manipulator

The SIGMA ML-Z manipulator is an ideal alternative to cranes and simple hoists. It allows to carry out the operations of lifting and handling the load in a specific direction. The manipulator enables to perform the necessary movements while handling the load, such as rotations in the vertical axis of the column and boom, also to put the load down in the required area. The gripper and its features are designed according to the individual requirements of given application.

Model Lift It - Pneumatic Controller

The LIFT IT pneumatic controller is an ergonomic handle, adapted to fast replacement of grippers designed for cable type manipulator. It is perfect solution for distribution centres and warehouses, where smooth and effective operation is required and various types of loads are being handled. Application of LIFT IT controller increases the precision, efficiency and speed of work in handling processes. The device is equipped with adapter for quick changing and installation of new grippers, control buttons of up/down moves with an option to adjust lifting and lowering speed of load handling (this is performed by pressure force), as well as proper signalling system ensuring safe operation. Standard version of pneumatic controller is equipped with hook gripper. SIGMA offers wide range of grippers to be applied with LIFT IT controller, we are also able to individually design the gripper tailored to customer’s needs.