- Home

- Companies

- Sigma Thermal, Inc.

- Products

Sigma Thermal, Inc. products

Direct Fired Heaters

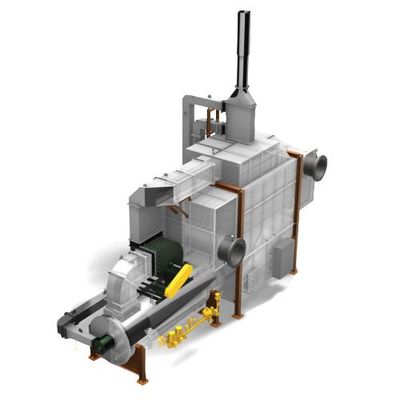

Sigma Thermal - Convection Heater

A convection style heater offers the benefits of a direct-fired heater while eliminating some of the drawbacks associated with radiant heat transfer. Radiant heat transfer can be undesirable in certain temperature-sensitive applications as radiant heat transfer tends to be more intense and unevenly distributed around the coil surface. Sigma Thermal’s convection style direct fired heater utilizes a separate combustion chamber and flue gas recirculation to reduce combustion chamber temperatures to 1,400F, thereby minimizing the impact of radiant heat transfer to the process coil.

Sigma Thermal - Radiant-Convective Heater

A radiant–convective style heater is the most well-known and commonly used style of direct-fired heater. These heaters utilize a bare tube radiant zone in combination with a bare / finned convection section. Vertical cylindrical, A-frame, and cabin style are the most common configurations. Sigma Thermal offers all types of radiant–convective heater designs including API 560 compliant systems.

Process Bath Heaters

Sigma - Direct Fired Reboiler

Sometimes referred to as a weir bath heater, this is a slight variation of a traditional water bath heater that does not utilize a process coil. This type of heater is most commonly used as a direct fired reboiler for amine and glycol solutions. The bath vessel contains a fire-tube and a weir at the end of the fire-tube. The process fluid is circulated through the bath vessel in direct contact with the fire-tube. After the process fluid is heated, it falls over the weir where the return line sends it back to the process user.

Sigma Thermal - Water/Salt Bath Heater

The bath solution is heated by a fire tube style burner submerged at the bottom of the heater vessel. Water-glycol mixtures are very common solutions for most low-temperature heating applications, and can typically be used up to 250F.

Waste Heat Recovery

NextGen - Emissions Reduction System + Power

To convert waste heat energy into usable electricity, Sigma Thermal has partnered with ElectraTherm, to offer an integrated package containing an Organic Rankine Cycle (ORC) generator, helical coil heater, condenser, and evaporator. The waste fuel is captured by an existing industrial process and used for power conversion. When the NextGen Emissions Reduction System + Power is utilized, gas and oil production, wastewater treatment plants, landfills, farms, and other waste fuel-producing facilities can greatly reduce emissions while minimizing or eliminating flaring.