2 products found

SINC Thermal LLC products

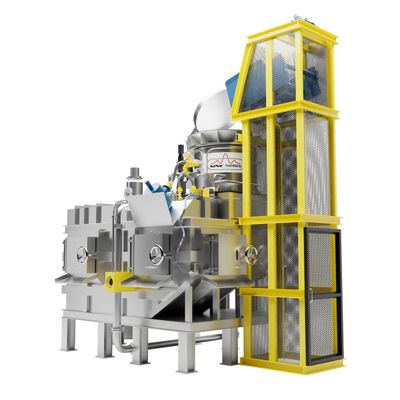

SINC Thermal - Freedom Shaft Melter - Efficient Aluminum Melting with Extended Cleaning Cycles

The Freedom Shaft Melter by SINC Thermal LLC represents a significant advancement in aluminum melting technology. Engineered by Nippon Crucible Corporation, this patented melter leverages a low-oxidation design to optimize production efficiency. It allows foundries to operate for extended periods, up to 18 months, without the need for frequent holding bath cleaning. This is achieved through independent melting and holding burners that offer precise thermal control, reducing oxidation and metal loss while enhancing metal purity and decreasing inclusions. The melter significantly minimizes energy consumption and reduces downtime, thereby increasing productivity. Its unique capabilities result in longer operational periods with less metal-rich drag out and decreased dross formation, resulting in overall cost savings and improved asset longevity. The Freedom Shaft Melter is constructed to support better operator efficiency while lowering operational and energy costs, positioning it as a valuable tool for any foundry focused on high-quality production and operational cost reduction.

SINC Thermal - Jet Melter Furnace for Aluminum Production

SINC Thermal LLC has been a leader in tower melt technology for over four decades, with their Jet Melter Furnaces standing as a testament to efficiency and reliability in aluminum production. These furnaces effectively address the need for rapid, low dross aluminum melting by preheating ingot and scrap materials in the stack section using exhaust gases from the melting hearth. This innovative design ensures optimal conditions for material melting, allowing molten aluminum to flow swiftly into the bath section for precise temperature control. An external pocket in these furnaces permits the safe transfer of molten aluminum either by ladling or pumping, while optional tapping valves can direct the liquid metal to holding furnaces where needed. This system is designed for efficient and energy-conscious operations, reflecting SINC Thermal's commitment to providing advanced solutions in metallurgical processes.