Sorbacal | Lhoist Group products

Sorbacal - Standard Hydrated Lime

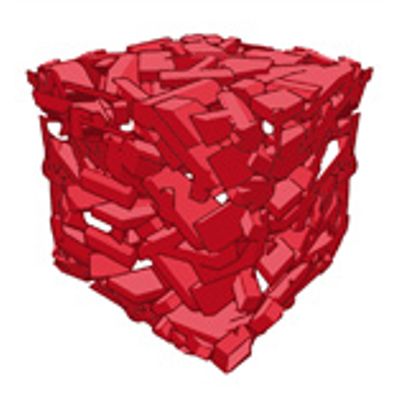

Sorbacal® SPS is an activated enhanced hydrated lime with the highest acid gas removal performances. It was developed especially for removing acid gas pollutants using dry or combined processes. Sorbacal® SPS has a specific surface area of typically 40 m²/g (BET) and a porous volume of typically 0.20 cm³/g (BJH). The particle size of Sorbacal® SPS is designed for optimal reactivity, flowability and handling.

Sorbacal - Standard Hydrated Lime

Sorbacal® SP is an enhanced hydrated lime especially designed for DSI applications. Its specific surface area of typically 40 m2/g (BET) is two times higher than standard hydrated lime, and its porous volume is typically 0.20 cm³/g (BJH), compared to 0.08 cm³/g for standard hydrated lime. These qualities make the material significantly more effective for acid gas removal than standard hydrates. The particle size of Sorbacal® SP is designed for optimal reactivity, flow ability and handling.

SORBACAL - Premium Grade Hydrated Lime

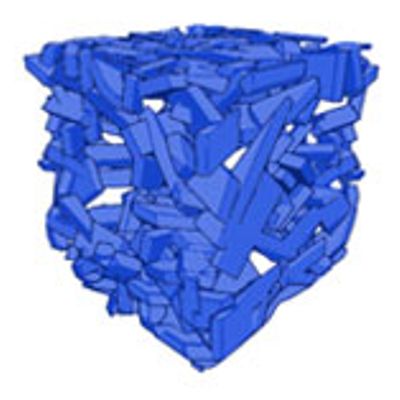

Sorbacal® H is a hydrated lime or calcium hydroxide (Ca(OH)2) of high quality for emission control applications. Compared to standard hydrates, it has a higher specific surface area of typically 15-22 m²/g (BET), as well as a porous volume of typically 0.08 cm³/g (BJH). Both enhance acid gas capture. A white, dry, ready-to-use powder, Sorbacal® H is used directly in dry processes, as well as for producing lime slurry (milk of lime) for semi-wet processes.

Sorbacal - Premium Grade Hydrated Lime with Increased Surface Area

Sorbacal® HSH is a hydrated lime or calcium hydroxide (Ca(OH)2) specifically developed in Brazil and used in dry sorbent injection (DSI) or circulating dry scrubber (CDS) processes. Sorbacal® HSH has a higher specific surface area than a standard hydrate, typically 25 m²/g (BET), and a porous volume of typically 0,1 cm³/g (BJH).

Sorbacal - High Surface Area, Extra-Fine Hydrated Lime

Sorbacal® A is a hydrated lime or calcium hydroxide (Ca(OH)2). It is characterized by a high specific surface area of typically 35 m²/g (BET), a porous volume of typically 0.12 cm³/g (BJH) and more specifically a very fine particle size distribution (average diameter of 2 - 3 µm). A unique production process results in improved flow behavior. This makes Sorbacal® A the product of choice for all FGT applications requiring good sorbent dispersion, such as an ESP dry process at 300-350°C, or furnace sorbent injection (FSI) at temperatures of 850-950 °C.