SPS Engineering, Inc. products

SPS - Drives for Clarifiers & Thickeners

The drive unit is the mechanical core of clarifier or thickener that produces low speed high torque rotation of the sludge collector arms to permit positive sludge collection and removal for proper unit operation. SPS designs, manufactures, assembles and tests the drive units for our equipment and also offers replacement drive units for aging clarifiers. SPS drive units are reliable, heavy duty, low maintenance and very operator friendly.

SPS - Mechanical Flocculators

Mechanical Flocculators are used in coagulation and floculation processes where solids are small (colloidal) and can be relatively dispursed. In order to settle these particles chemicals are added along with energy to neutralize charges and allow particles to collide then agglomerate forming larger floc particles that permit settling in a clarifier. SPS manufactures several common types of mechanical mixers for use in flocculation.

SPS - Grit Classifiers

Grit collectors and classifiers are utilized for removal of sands and grit from wastewater to protect against abrasive wear on mechanical equipment and sludge pumps. Separated grit is dewatered and washed on a grit classifier cyclone separator then discharged into bin for disposal. SPS manufactures classifiers and collectors for use in grit collection.

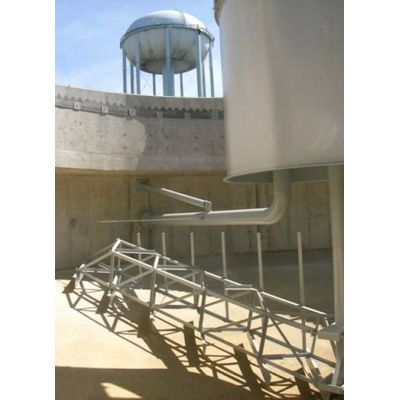

SPS - Rotary Distributors

Distributor arms are used on trickling filters which foster attached growth biological microorganisms to stabilize organic matter in the wastewater. The sloughing of excess microorganism that separate from the media surface are collected in a clarifier ollowing the trickling filter. SPS manufactures rotary distributor arms with nozzles that evenly apply inflow to the surface of the filter media while improving air contact through spreading out and dispursing.

Primary & Secondary Clarifiers

SPS - Primary Clarifiers

Primary purpose: Remove solids that pass through headworks and grit equipment. Lessen organic loading on following biological process. Buffer flow and load stabilization to secondary process / split stream treatments.

SPS - Secondary Clarifiers

Primary purpose: Separate and remove solids/biomass produced in biological process in manner that suits process goals (rapid sludge removal, detention time, etc.). Thicken solids for recirculation and process reuse. Store biomass as buffer to prevent process upsets.

Process Clarifiers

SPS - Solids Contact Reactor

Combines: Coagulation/flocculation, Internal recirculation, clarification and sedimentation. Treat raw surface/ground water. Softening, Iron & Heavy Metals removal (precipitation). Flue Gas Desulphurization. Prior Demineralization. Catalyst recapture. Power. Mining. Pulp Paper.

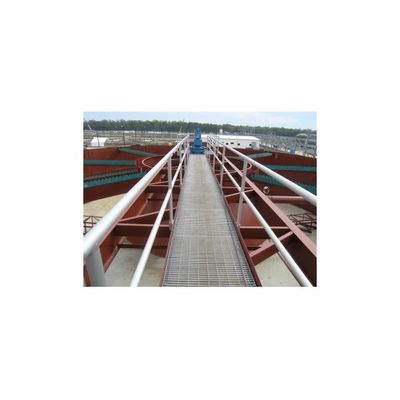

SPS - Conventional Clarifiers

Tank (concrete or steel), Side Feed Influent pipe type SCBC / SCCC, Center Column Influent type SCCC, Feedwell, Sludge Collection Rake Arm, Angled Blade, Sludge Withdrawal, Center Hopper, Torque Shaft or Torque Cage, Drive Unit, Drive Access Bridge/ Walkway, Weirs.

SPS - Flocculating Clarifiers

Combine: Coagulation/flocculation, clarification and sedimentation.

Thickeners

SPS - Gravity Thickeners

Thickeners reduce solids volume through concentration of sludge with gravity driving the process.Sps manufactures thickener mechanisms to best suit the thickening process.Steel shells or tanks are also available.The most widely used thickeners are depicted below.