Stainless Processing, Inc. products

Stainless Steel Plate

SPI - Saw Cutting Stainless Steel Plate

Until more recent advances in stainless cutting technology, most plate was cut with a high-speed band saw. Accuracy is somewhat sacrificed, but saw cutting offers lower heat affected zones than machining. There are applications that still make sense for saw cutting, although it does not offer the flexibility and shape options that other cutting methods do.

SPI - Water Jet Cutting Plate

High-pressure water and the addition of abrasives cut a wide variety of stainless steel thicknesses with precision. Water jet cutting is often used when the materials being cut are sensitive to the high temperatures generated by other methods like plasma cutting. During the fabrication process, Water Jet cutting is most often used when the application requires less heat be applied to the part.

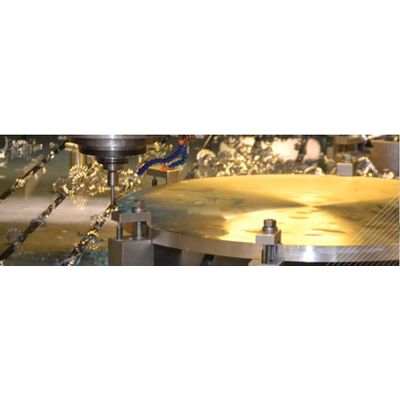

SPI - Machine Cutting Plate

Often faster and less expensive than newer automated methods, machine cutting includes the in-line ability to drill, tap and machine all parts of a stainless steel plate. Machine cutting uses traditional, as well as cutting-edge, machine shop tools to cut stainless plate to the customer`s specifications.

SPI - Bevel Cutting Plate

Stainless Processing, Inc`s plasma cutting machines feature bevel cutting capabilities that allow for very diverse and very precise angled cuts on any edge of steel plate. A computer controlled bevel head torch cuts beveled edges in any number of shapes and configurations. From simple rectangular tank or vessel shells, to irregular shapes, Stainless Processing, Inc. produces your parts to your exact specifications. See below for a sample of the variety of beveled edges that SPI`s plasma cutting process can produce.

Stainless Steel Grades & Gauges

SPI - Austenitic Grades

Austenitic grades are those alloys which are commonly in use for stainless applications. The austenitic grades are not magnetic. The most common austenitic alloys are iron-chromium-nickel steels and are widely known as the 300 series. The austenitic stainless steels, because of their high chromium and nickel content, are the most corrosion resistant of the stainless group providing unusually fine mechanical properties. They cannot be hardened by heat treatment, but can be hardened significantly by cold-working.

SPI - Martensitic Grades

Martensitic grades were developed in order to provide a group of stainless alloys that would be corrosion resistant and hardenable by heat treating. The martensitic grades are straight chromium steels containing no nickel. They are magnetic and can be hardened by heat treating. The martensitic grades are mainly used where hardness, strength, and wear resistance are required.

SPI - Ferritic Grades

Ferritic grades have been developed to provide a group of stainless steel to resist corrosion and oxidation, while being highly resistant to stress corrosion cracking. These steels are magnetic but cannot be hardened or strengthened by heat treatment. They can be cold worked and softened by annealing. As a group, they are more corrosive resistant than the martensitic grades, but generally inferior to the austenitic grades. Like martensitic grades, these are straight chromium steels with no nickel. They are used for decorative trim, sinks, and automotive applications, particularly exhaust systems.

SPI - Duplex Grades

Duplex grades are the newest of the stainless steels. This material is a combination of austenitic and ferritic material. This material has higher strength and superior resistance to stress corrosion cracking. An example of this material is type 2205. It is available on order from the mills.

SPI - Precipitation Hardening Grades

Precipitation hardening grades, as a class, offer the designer a unique combination of fabricability, strength, ease of heat treatment, and corrosion resistance not found in any other class of material. These grades include 17Cr-4Ni (17-4PH) and 15Cr-5Ni (15-5PH). The austenitic precipitation-hardenable alloys have, to a large extent, been replaced by the more sophisticated and higher strength superalloys. The martensitic precipitation-hardenable stainless steels are really the work horse of the family.

SPI - Super Alloy Grades

Superalloys are used when 316 or 317 are inadequate to withstand attack. They contain very large amounts of nickel and/or chrome and molybdenum. They are usually much more expensive than the usual 300 series alloys and can be more difficult to find. These alloys include Alloy 20 and Hastelloy.