Steinmüller Babcock Environment GmbH products

Flue Gas Cleaning

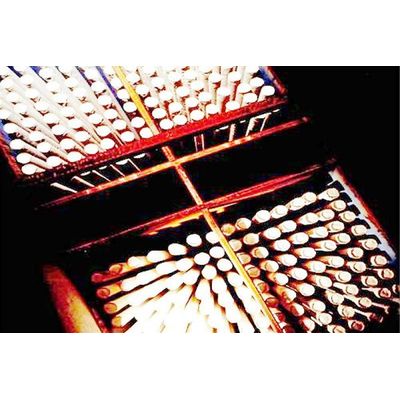

Fabric Filters

Our fabric filter technology has proven its worth in many different areas of application and industries. Even in difficult applications, separation rates of over 99.9% are achieved. The spectrum ranges from small and medium filters, for example in industrial applications or waste incineration plants, to large filters with up to 10,000 filter bags in large coal-fired power stations. The solid and effective structure means they can be used in extreme conditions, with low maintenance and at the same time large availability. As well as for pure dust separation, fabric filters can also be used in combination with activated carbon as an entrained flow absorber to remove gaseous pollutants such as mercury or dioxins.

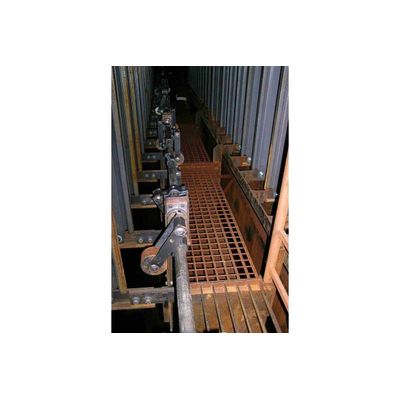

Wet Electrostatic Precipitators

The function of dust separation in electrostatic precipitators is based on an electric field that is built up between the high-voltage discharge electrodes and the earthed collecting plates. When the flue gas flows through the electrostatic filter, the dust particles become electrically charged and are separated at the electrodes through the effect of the electric field forces.

Electrostatic Precipitator

The function of dust separation in electrostatic precipitators is based on an electric field that is built up between the high-voltage discharging electrodes and the earthed collecting plates. When flue gas flows through the electrostatic precipitator, the dust particles become electrically charged and are collected at the plates through the effect of the electric field. Fine dust can be removed very successfully from the gas in this manner.