Sterling Systems & Controls, Inc. products

Sterling - Bag Dump

The Bag Dump Station is typically used to empty small bags of bulk solid material, such as a wide variety of powders, into a bulk material handling and processing system. The bag dump is typically used to empty small bags of bulk solid material into supply bins or a feeding system. The basic unit usually consists of a hopper, hinged lid, outlet cone, bag support shelf, and grate. The Sterling Systems & Controls’ dump station is custom engineered to meet the exact requirements of our customers’ process, often including dust collection to control the spread of dust during the dumping process. Bags are lifted up and set on the grate where they are then opened and the material emptied into the hopper. The grate helps to keep the bag or parts of it from falling into the hopper. Dust collection is such that a downward airflow is pulled below the grate, pulling the dust away from the operator. Materials of construction can be mild or stainless steel.

Batching and Weighing

Sterling - Batching Systems

Sterling Systems & Controls, Inc. can provide Automatic and Semi-Automatic Ingredient Batching Systems that will improve the efficiency of your powder and bulk, or liquid, material handling process. We specialize in custom designing, engineering, and manufacturing batching systems to increase your process performance, improve product consistency, eliminate product waste, and provide robust production data collection and reporting. Ingredient batching systems can also include the blending/mixing operations, and other process equipment and controls.

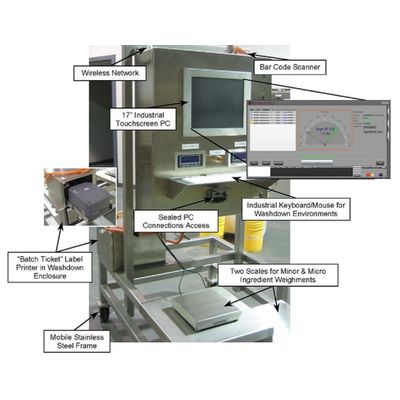

Sterling - Hand Prompt Batching Station

Sterling Systems & Controls, Inc. designs and manufactures semi-automatic hand prompt stations (picture shown with optional bag dump) to meet the specific requirements of each customer as needed. The semi-automatic hand prompt batching station serves a wide range of industrial applications where the negative effects of time consuming and problematic manual batching needs to be eliminated. The hand prompt batching station is a semi-automatic batching system providing automated operator instructions or prompting, ingredient validation and lot tracking, automatic weighing with over/under tolerance control, etc. This system uses operator involvement to assist in the batch creation and will eliminate bad batches that result from operator error and interruption that occurs in the manual batching process.

Sterling - Kitchen Batching System

Sterling Systems & Controls, Inc. provides many types of batching systems. A popular type of batching system in many industries, but most especially in the food and related foodstuffs industries is the Semi-Automatic Kitchen Batching System, a.k.a the Kitchen System. The semi-automatic kitchen batching system uses similar automation technology, both hardware and software, as the semi-automatic hand prompt station and automatic batching systems. As with the hand prompt batching stations, the semi-automatic kitchen batching system requires an operator to be present. The primary role of the operator in a semi-automatic kitchen batching system is to manually feed ingredient materials into the batching collection container on the weigh scale of the system.

Sterling - Material Weighing Systems

Sterling Systems & Controls, Inc. offers a variety of material weighing systems for many industries and applications. Each system is customized to meet the exact requirements and demands of our customer. Material Weighing Systems are useful for automatic batching of multiple ingredients using single or multiple scales. A semi-automatic material weighing system for batching applications requires operator assisted feeding of ingredients with automatic operator instructions, weighing and lockouts to ensure there will be no more missed ingredients due to operator interruption or error. These material weighing systems for ingredient batching ensure batch integrity, quality & consistency.