- Home

- Companies

- Stiefel Holding AG

- Products

Stiefel Holding AG products

Stiefel - Grate System

The size of the grate is designed to handle a high variation of calorific values. The completely water cooled Stiefel grate is part of an on going development where the current technology is applied, used together with the latest features which include:

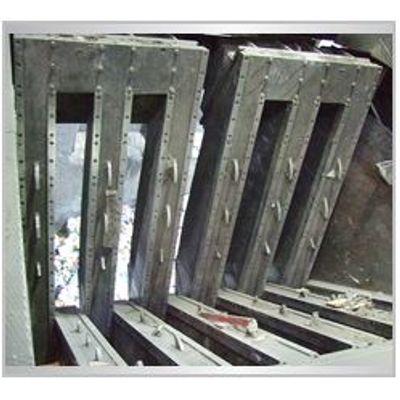

Stiefel - Waste Bunker Door

The doors are a vital part of the bunker and have to resist the harsh treatment of refuse delivery. Depending on the conditions, they can be constructed as a swinging, or lifting type. Due to their solid construction, the doors are highly suitable for stacking up waste behind them. They are state-of-the-art and meet all the current safety criteria and standards.

Stiefel - Bulky Waste Cutter

The bulky waste cutter is used to cut pieces to an optimal size for delivery to the grate and for uniform combustion. The cutter is fed by an overhead crane system. Afterwards, the cut material falls back into the waste bunker. Due to the design of the outlet chute, the cut materials have a different route to the feeder. This process simplifies the re-feeding of large pieces.

Stiefel - Feeder Chute

The chute is designed to prevent the waste from being compacted and allows for a uniform distribution across the grate. This is the basic requirement to obtain an even combustion.

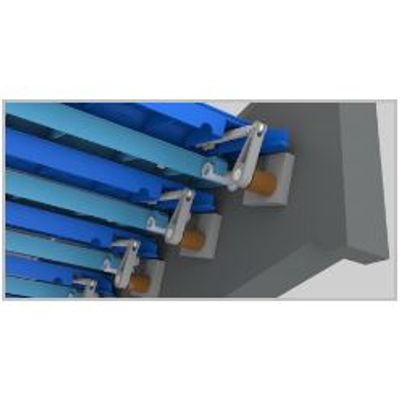

Stiefel - Internal Grate Drive System

Due to the impressive simplicity of the mechanism, the internal drive system is the most direct and straightforward drive option. A replacement of the few lightweight components is easily possible during routine maintenance periods. A hydraulic cylinder installed on each side of the grate step, allow a linear movement of each step. Positioning and synchronisation is achieved by an integrated measuring and sensor system. None of the drive components penetrate the grate side walls; therefore the grate construction is totally enclosed.

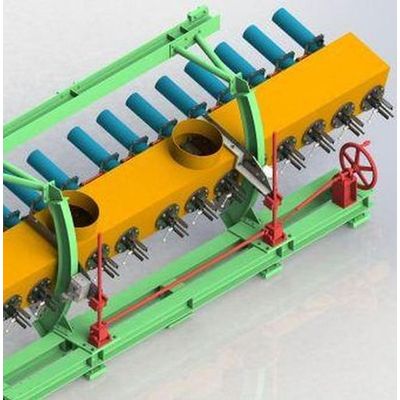

Stiefel - External Grate Drive System

Its main advantage is the possibility of immediately being able to replace a failing drive element whilst continuing normal operations. The externally applied force is transmitted through the grate side wall, to the grate step by a shaft. High quality materials are used to ensure the most effective compact drive unit. More available space outside the grate allows the implementation of various cylinder sizes. Therefore, more powerful drive cylinders can be installed instead of the standard ones a particular advantage for wide grates.

Stiefel - Grate Retrofit

Due to the patented retrofit system, the widely spread reciprocating grate is ready to go a step further!

Stiefel - Secondary Air System

The secondary air system blows air into the combustion chamber for final combustion. Its feeding depends on the loading, the calorific value and the gas quality. Each nozzle is equipped with an internal cone where the beam pulses as well as the penetration can be individually regulated. The air nozzles are water cooled and the direction can be changed by an angle of up to 30 degrees. The high flexibility of the combustion air enables injecting the air into the combustion chamber to be done with great accuracy. If the conditions vary, adjustments can be made at any time.

Stiefel - Ash Discharger

The function of an ash discharger is to transport and remove the remaining slag after complete combustion. It also forms the seal between the combustion chamber (low pressure) and the environment outside the incinerator.