STM Technologies S.r.l. products

Chopped Strand Mat

STM offers complete chopped strand mat lines employing latest-generation technology developed from direct production experience. STM equipment produces mat of different gram weights (from 150 to 1200 g/m2) and quality (powder or emulsion binder).

Lime Plant

STM LIME Srl is the new subsidiary company of STM Technologies Srl.,supplying lime turn key production lines with most advanced technology based on more than 40 years experienced know how of its technical staff.

Insulation

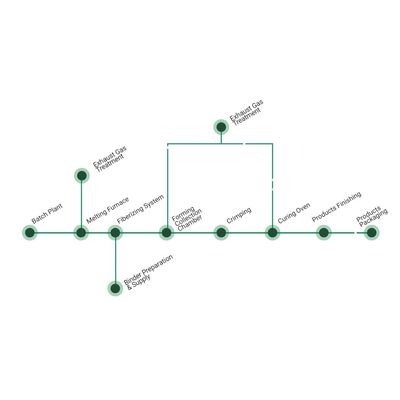

Glass Wool Lines

STM offers complete glass wool production lines employing latest-generation technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM). At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping. STM covers all of these production steps, with distinctive know-how on the hot end of the line: for example, it has developed its own, patented fiberizing processes and machines and it can provide any type of binder together with the related production plant. Thanks to these competences, STM can provide the complete production line, managing all the technological aspects of the project.

Stone Wool Lines

STM offers complete stone wool production lines employing latest-generation technology to manufacture panels, rolls and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, ASTM, etc.). The stone wool production line consists of a series of sections where the raw materials are transformed into thin fibers, collected, and packed into the final insulating products. The line is conventionally split into a “HOT” end and a “COLD” end. At the hot end, the raw materials are mixed, melted, fiberized, impregnated with a binding agent, formed into a mat and cured. At the cold end, the mat is cut to shape and packed. STM invests human and financial capital to develop new machines for improved plant efficiency and product quality. The result is state-of-the-art equipment and innovative design solutions.

Microfibers

STM offers complete glass microfiber production lines employing latest-generation rotary technology. It has developed a special fiberizing machine as an alternative to the traditional flame attenuation process. The STM rotary process provides the same fiber diameter as the flame attenuation method, using one third of the energy and delivering a much higher pull per production unit. Microfiber production capacity ranges from 1.2 to 5 tons/day, for diameters from 1,5 to 3 microns. Products are DIN compliant. Microfiber is a primitive fiber produced with a variety of glass formulas. For some uses it may contain special binder or additives. STM provides complete glass microfiber production lines comprising raw materials dosing and mixing, melting furnace, fiberizing and forming section, binder preparation, curing oven, cutting and packaging.