- Home

- Companies

- Stratec Se

- Products

Stratec Se products

Air Displacement Pipettor

STRATEC air displacement pipettors are fully automatic pipetting modules using disposable tips (DiTis). The usage of DiTis prevents cross-contamination. Integration of the syringe into the pipettor housing close to the DiTi, results in the omission of a tubing system connecting a DiTi to an externally placed syringe. Minimized internal air volumes lead to highest pipetting performance and precision. Considering our partner’s design requests, STRATEC offers two configurations with different characteristics with regard to individual space and footprint requirements. Both configurations have the same functionality.

Module

Stratec - Fully Automatic Air Displacement Pipettor

STRATEC air displacement pipettors are fully automatic pipetting modules using disposable tips (DiTis). The usage of DiTis prevents cross-contamination. Integration of the syringe into the pipettor housing close to the DiTi, results in the omission of a tubing system connecting a DiTi to an externally placed syringe. Minimized internal air volumes lead to highest pipetting performance and precision. Considering our partner’s design requests, STRATEC offers two configurations with different characteristics with regard to individual space and footprint requirements. Both configurations have the same functionality.

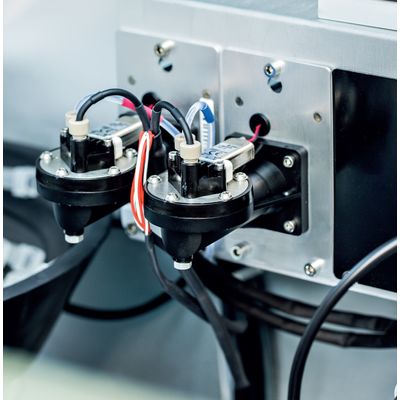

Stratec - Perestaltic Pump

Perestaltic pumps are highly convenient for handling problematic liquids, especially waste. Tube Kits are the only components getting in contact with the transferred media, ensuring a strict seperation of mechanics and fluids. Highest flexibility is garanted by equipping the pump with up to three casettes. Each casette includes aTube Kit with up to three channels. Pressure shoes contain springs ensuring constant pressure independent from the casette configuration and the number of channels over lifetime.

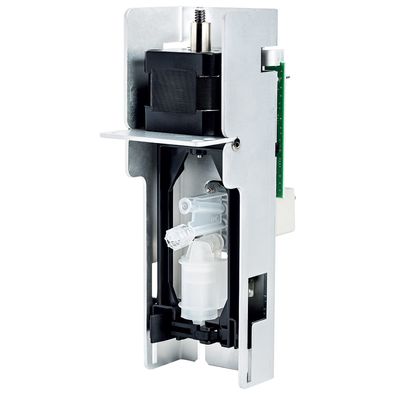

Stratec - Pump

The LCM Pump combines highest precision and chemical resistance, ideal for handling aggressive liquids. A hermetically sealed chamber prevents crystallization, that occurs in piston pumps. Therefore, frequently flushing the system (which is in some cases not even possible due to the aggressiveness of the liquids) is not required in order to prevent crystallization. Due to the implemented LCM principle, this pump is virtually maintenance free. Air-free filling of the coupling liquid between the membrane and the bellow, ensures a prpoer transmission of the displacements. The main application for the LCM Pump is the precise dispensing of starter and trigger reagents. Alternatively, it can be used as an oil pump to seal arrays in a fluidic chip.

Stratec - Syringe Pump

The Syringe Pump is a self-contained 30 mm syringe module, covering various liquid handling applications such as automated pipetting, dispensing and diluting. The pump comes with sensors for step and position monitoring and with an A/D converter to support clot detection. Standardized mounting and dimensions allow far-reaching compatibility with other modules from other manufacturers.

Stratec - Piston Pump

Several options for the volume delivery are possible, ranging from one single stroke to freely adjustable individual strokes (multiple dispense). Hence, the Piston Pump is a perfect choice for reliable wash buffer dispensing. Wearing parts like the piston and cylinder unit are plastic components and easy accessible. This allows the components to be easily exchanged resulting in an overall cost reduction due to the application of more cost efficient materials.

Stratec - Degasser

The Degasser reduces the amount of dissolved gas in liquid, consequently no air bubbles can coalesce in the tubing system. Removing dissolved and undissolved gases in deionized (DI) water ensures consistently high pipetting precision and accuracy, especially for small volumes in liquid filled pipetting systems. A vacuum pump in combination with a semipermeable membrane enables the system to degas and debubble bypassing fluids. An integrated sensor monitors the pressure within the vacuum chamber. Additional sensors constantly monitor the performance and functionality. The membrane lifetime depends on the quality of input water, which for DI Water could be several years.