- Home

- Companies

- Struvite Removal

- Products

Struvite Removal products

Scale Remover Industrial Descaler STSR

Finding any scale including water scale or limescale in your plant or operation can be a huge problem for operations and operators, once located it should be dealt with immediately to restore to 100% efficiency. Our product has been used around the world for years for different descaling applications, we can even customize the product to your needs, for example to foam, or added thickener for vertical surfaces. Scale Remover is an Industrial Descaler that can be used in many different applications and industries. Scale Remover is non-corrosive to steel, non-corrosive to unbroken skin, environmentally friendly and cost-effective. Email evan@struviteremoval.com or call +1-310-715-3070, and for more info visit struviteremoval.com.Struvite Preventer STSP - Prevention for Wastewater Treatment Plants

Struvite Prevention & Removal is a hot topic for wastewater treatment plants (WWTP) and Concentrated Animal Feeding Operations (CAFO). The overflow line off the anaerobic digester is often the first piece of equipment to get choked by a deposit of hard rock Struvite crystals. Struvite tends to form in the anaerobic digester and on the pipes and equipment involved in dewatering the sludge solids. The worst Struvite precipitation often builds up in the sludge transfer lines in a WWTP or in the recirculation pump from a lagoon in CAFO. The turbulent areas, which are their pump heads, pipe bends and sludge transfer lines see a release of CO2 and the formation of struvite crystals. The best method to remove & prevent struvite is to have a program that limits the availability of the base components of Struvite to react with each other. Email evan@struviteremoval.com or call +1-310-715-3070, and for more info visit struviteremoval.com.Struvite Wastewater Treatment

Wastewater treatment plants (WWTP) are in every major city in the United States. These plants are responsible for human sewage disposal and treating industrial waste and agricultural wastewater for safe return to our oceans, rivers, ponds, and industrial parks for useable watering. As long as these huge industrial complexes have clean and open pipes, wastewater treatment plants operate efficiently and cost-effectively. When their pipes begin to clog because of Struvite deposits, however, plant efficiency falls precipitously and the cost of operating the plant increases quickly.

Struvite Remover STSR

Struvite - Recreational Vehicle (RV) Struvite & Scale Remover

Struvite is a crystal that occurs naturally, mostly in places such as wastewater treatment plants (WWTP), confined animal feeding operations (CAFO), food processing, and other industries where magnesium, ammonia, and phosphate are present. Struvite can also form in Recreational Vehicles (RV), whereas it has magnesium, ammonia, phosphate in the holding takes due to the hard water, ammonia, and other organic matter coming together. The struvite or scale can range in color and thickness. Struvite can prove to be a major problem for Recreational Vehicle (RV) owners as hydro-flushing, mechanical cleaning, or the use of acids are needed to rid of the buildup that can cause clogs in the pipes and systems.

STSR - Struvite Remover and Industrial Descaler Soaks & Recirculations

Our Struvite and Scale Remover STSR has been used in many recirculations as it is the most effective application as opposed to soaks, low-pressure sprays, and foaming. With recirculation, STSR is able to have constant contact with the scale buildup, agitation, as well as providing the opportunity to capture the solids broken down from the removal process, enabling the product to be more efficient and focus on the buildup as opposed to strictly dissolving.

Scale Remover STSR

Struvite - Heavy Duty Industrial Rust Remover

Industrial rust remover products are crucial for addressing the industrial rust removal issues in sectors such as oil & gas, petrochemical, transportation, and many other industries where rust buildup can be a common issue in heavy-duty industrial equipment. Scale remover STSR is the ultimate industrial-grade rust remover for eliminating rust and scale on surfaces such as stainless steel and iron. Industrial Rust Remover STSR is a chemical rust remover product that is also an alternative for strong acids such as Hydrochloric acid (also known as muriatic acid) and sulfuric acid. These acids can be highly corrosive and pose serious health and safety risks. Our buffered acid is cost-effective, non-hazardous, non-corrosive to steel and unbroken skin, and poses minimal risk to operating personnel and equipment involved.

Industrial Limescale Remover & Industrial Calcium Remover

What is limescale and calcium carbonate? Limescale tends to be hard, white or off-white in color, which forms from hard water, which contains calcium and quite often magnesium. The color can vary with the presence of other iron components and the operation. This form of scale can be found while dealing with hot water pipework, old pipe and other areas where dealing with hard water.

Struvite Removal Products - Degreasers, Deodorizers and H2S Neutralizer

H2S Scavenger and Neutralizer of Ammonia and other Gases

Hydrogen Sulfide (H2S) is flammable, colorless, smells like rotten eggs, and can be a hazardous gas. Hydrogen Sulfide (H2S) can occur naturally, but can also be formed by the breaking down by bacteria of organic materials such as different forms of waste, such as sewage. The gas can be formed from many different industrial activities such as drilling, refining, wastewater treatment, etc.

Struvite Removal Products

Struvite - Free Lab Testing

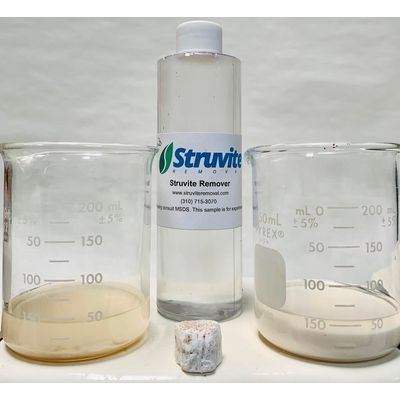

Struvite Removal offers free lab testing to test the effectiveness of our Struvite Remover and Scale Remover STSR. The goal of the test is to determine the product to scale ratio as well as the spent pH to have as a benchmark for when the product is done working. Please refer to the bottom of the page to see an example of an actual test that we perform free of charge, and that you can test for yourself. For the entire procedure and further information, please download the document on the bottom right, or request it from our team.

STSP - Prevention in Struvite Wastewater Treatment

Struvite Formation Issues: Struvite Prevention is a hot topic for discussion groups and seminars where the participants are plant managers and operators of wastewater treatment plants (WWTP) and Concentrated Animal Feeding Operations (CAFO). The overflow line of the anaerobic digester is often the first piece of equipment to get choked by a deposit of hard rock Struvite crystals. Struvite tends to form in the anaerobic digester and on the pipes and equipment involved in dewatering the sludge solids. The worst Struvite precipitation often builds up in the sludge transfer lines in a WWTP or in the recirculation pump from a lagoon in CAFO. The turbulent areas, which are their pump heads, pipe bends, and sludge transfer lines see a release of CO2 and the formation of struvite crystals. The best method for struvite wastewater treatment and to prevent struvite is to have a program that limits the availability of the base components of struvite to react with each other.