- Home

- Companies

- Stuart Steel

- Products

Stuart Steel products

Backfill - Loresco

Loresco - Super Conducting Backfill for Cathodic Protection

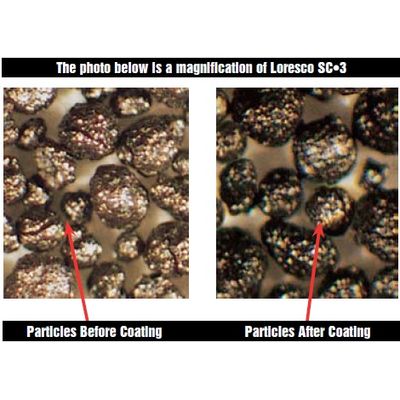

Loresco SC-3 is engineered for cathodic protection applications to enhance system efficiency and longevity. This dust-free product is characterized by its exceptional conductivity properties due to its semi-graphitized carbon particles, which are produced by calcining high-quality carbon at over 1250° C under strictly controlled conditions. To augment the conductivity further, the particle surfaces are modified to improve contact conductance, ensuring optimal electronic current transfer. A special surfactant addition reduces surface tension for superior compact settling in water, facilitating easy installation by mixing, pumping, or pouring, particularly advantageous in deep anode systems. The SC-3's low resistivity, high fixed carbon content exceeding 99.35%, and bulk density of 74 lbs. per cubic foot contribute to its robust performance, extending groundbed life while minimizing operational costs, ideal for high current installations.

Cable & Wire

Stuart Steel - Moisture and Heat-Resistant Thermoplastic Wire

The moisture and heat-resistant thermoplastic wires, identified as Type THW and THW-2, are specifically designed to cater to demanding electrical applications. THW wires are rated for 75°C in both wet and dry environments, while THW-2 can withstand up to 90°C under similar conditions. These wires are constructed using flame-retardant, moisture, and heat-resistant polyvinyl chloride (PVC) insulation, ensuring durability and safety in challenging environments. The products comply with the stringent UL 83 standard, underscoring their reliability for electrical insulation. Additionally, they meet ASTM B-8 and B-3 specifications, reflecting their adherence to current industry standards. Such technical compliance highlights these wires as suitable for extensive usage in environments requiring robust performance and dependability.

Casing Material - Casing Filler

Trenton Fill-Coat - Cold-Applied Wax Casing Filler for Corrosion Prevention in Pipe Casings

Trenton Fill-Coat #6 is a specialized petroleum-based wax casing filler compound designed for cold application in environments with temperatures as low as 50°F (10°C). This product is particularly suitable for use in bridge abutment casings, offering a reliable solution for preventing corrosion by filling the annular space of gas distribution systems. The compound not only protects against corrosion but also prevents the ingress of water into wax-filled casings, ensuring the longevity and integrity of the cased pipe structures. Designed for elevated temperature conditions, the product can be seamlessly applied using various portable air-powered mastic pumps, which are available in different capacities. Installation involves filling the casing annulus completely, followed by sealing the ends with appropriate materials such as Trenton FillPutty™, Trenton #2 Wax-Tape®, or epoxy fillers. Packaged in 55-gallon drums, Fill-Coat #6 stands out as a robust option for aboveground application needs.