- Home

- Companies

- Studsvik AB

- Products

Studsvik AB products

Fuel and Materials Technology

Studsvik - Reactor Pressure Vessel (RPV)

Studsvik’s extensive experience in aging of metallic materials and components, notably Reactor Pressure Vessel (RPV) and Core Internals (CI), is now made available to organizations throughout the world seeking support with their plant aging management and life extension programs. Studsvik’s world renowned reputation of many years as experts in performing testing and analysis of RPV and core internal materials, on behalf of customers in Europe and USA, is offered to customers worldwide.

Waste Management Technology - Waste Treatment Technologies

Studsvik Freeze-Tec - Waste Treatment Technologies

Using our ground-breaking methods and state-of-the-art technology, Studsvik’s Freeze-Tec provides clients with an optimal solution to a multitude of waste management issues. We work closely with our customers to deliver an innovative and tailored service that offers significant benefits when handling, managing, and treating various materials such as sediments, sludges, and residues.

Studsvik - Batch Steam Reforming Technologies

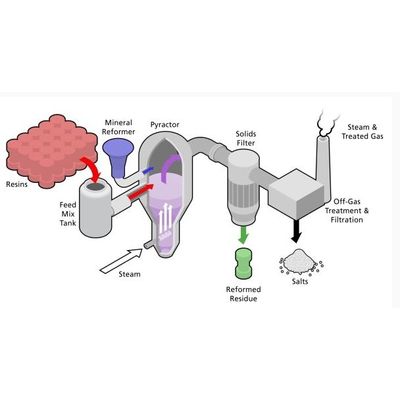

Studsvik’s batch steam reforming technology is applicable to thermal treatment of the types of wastes typically found in the nuclear industry. Studsvik has developed and continually improved upon this technology through many years of research and development and full-scale testing of the technology. Figure 1 shows the full-scale pyrolysis test unit.

Studsvik - Model FBSR - Waste Treatment Technologies

Studsvik has developed and patented a waste treatment technology based upon the use of fluid bed steam reforming technology. This innovative radioactive waste treatment process is commonly referred to as FBSR. Various applications of this technology have been deployed for the treatment of radioactive wastes generated from government and commercial nuclear operations in the United States, Europe, and Asia.