Sunnen Products Company products

Other Products

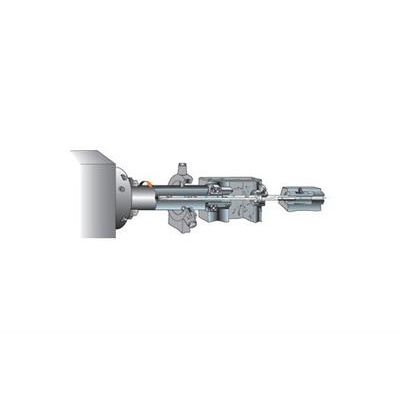

Internal Profiling Boring Tool

BTA Heller Inc. has developed a tooling concept for internal contour boring of components with pre-existing holes. This development was prompted by industries need for internal undercuts and internal contours that are generally too deep or too complicated for single point boring bars. Basically, the bottle boring tool is designed to ID contour bore a specific component and is generally furnished as an assembly and not as an add-on for existing tooling.

Form Boring Tools

Aside from the majority of components that require straight through bores, there are many components that require blind hole Form Toolsbores. These bores usually require some sort of form at the bottom of the bore. BTA Heller Inc. offers its engineering expertise to design and then manufacture form boring tools that are specifically designed for such components.

Drilling Systems

Gun Drilling System

Gun drilling is the oldest and most widely used method of deep hole drilling employed by industry today. The drill or “gun drill” is generally a one piece assembly consisting of a hollow cylindrical drill driver that is brazed to a V-shaped crimped tube and finally assembled to a brazed-on solid carbide drill head. Both the crimped drill shank and the brazed-on carbide drill head form a kidney shaped cross section, whereby the open V-shaped section acts as a chip flute.

Single Tube System (STS)

The single tube system STS or sometimes referred to as the “BTA” system of drilling, is the reverse of a gun drilling system. Unlike the gun drill, the STS or “BTA” drilling system assembly consists of a drill head that is attached to a ground cylindrical tube by either an internal or external fast lead thread. The drill tube or boring bar is smaller in diameter than the drill head which forms an annular space between the hole being drilled and the OD of the drill tube or boring bar. This space is known as “oil room” and in conjunction with a coolant induction unit or a pressure head, makes it possible to direct filtered high volume coolant to the drill head cutting edge.

Double Tube Drilling Systems (DTS)

The double tube system “DTS” or sometimes referred to as the “Ejector” system of drilling is where the coolant is supplied at the machine spindle through a special coolant inducer or connector. As the name implies, this drilling system consists of an outer and inner tube that is connected to the coolant inducer at one end and to a drill head at the other end by means of a fast lead, four-start thread.

Industrial Honing Machines - Horizontal Machines

Sunnen - Basic Honing Machine

The Sunnen MBB-1660 prepares a job shop for any type of I.D. work. One of our most versatile honing machines, the MBB-1660 guarantees precision sizing, geometric accuracy and a highly controlled finish on every part. Its quick setup and easy customization makes it a highly economical choice for short-run jobs in both production and salvage settings.

Lapping Machines

Sunnen - Lapping Machine

Sunnen`s new SVL-2115 automated lapping machine brings increased productivity and part consistency to what is traditionally a manual process. Based on the same machine platform as the popular SV-2100 honing system, the SVL-2115 provides single setup processing of hydraulic valves, sleeves, fuel system components and other parts that are prone to distortion when honed. The walkaway system uses an index table to automatically lap and air gage bores throughout the cycle. Gage readings are fed back to the control and the cycle is repeated until the parts are within spec.

Sunnen - Lapping Tools

Sunnen’s patent-pending lapping tools (laps) were developed to work in tandem with the unique feed system in our popular new SVL-2115 lapping system. This combination of machine and tooling brings automatic operation, consistency and productivity to what had previously been a manual process. Tools are custom-designed to meet your bore diameter and length requirements.

Skiving and Roller Burnishing Systems

Sunnen - Skiving + Roller Burnishing Machines

Be it Single Tube, Double Tube, Gun Drilling, or other specialty drilling system, Sunnen has the engineering expertise and manufacturing capabilities to offer single source, turnkey solutions for your deep hole drilling applications.

Deep Hole Drilling

Sunnen - BTA Deep-Hole Drilling Systems

The new Sunnen SHDD-series is designed around the BTA deep-hole drilling process in cylindrical parts. However, it is also capable of a wide variety of other similar machine processes, including counter boring, pull boring, trepanning, bottom forming, and skiving/roller burnishing.