Superior Industries, Inc. products

Crushing Equipment

SUPERIOR Liberty - Liberty Jaw Crusher for Rock and Mineral Processing

The Liberty Jaw Crusher is a primary compression crusher engineered to handle high-capacity rock and mineral processing. It is designed for applications like ore mining, quarried stone, river gravel, and recycled concrete. The machine is built with high-strength castings and multiple maintenance-friendly features, ensuring robust performance and dependability. The Liberty Jaw Crusher operates by compressing materials between a fixed jaw and a moving jaw to break rocks into smaller sizes. This process continues until the material is small enough to pass through the bottom gap. Notable features include a mid-mount base frame for low-profile installations, an aggressive nip angle for consistent processing, high-grade cast steel components for durability, and a composite draft guard for ease of use and quiet operation. Superior Industries provides this jaw crusher to enhance operational efficiency and minimize downtime in crushing operations.

Screening Equipment

SUPERIOR Anthem - Inclined Screen

With robust construction and advanced screening mechanisms, the Anthem Inclined Screen ensures superior material separation, reduced downtime, and increased productivity. Anthem Screens are typically used in fine and coarse screening applications or for operators requiring a scalping stage, which removes oversized materials before the crushing or processing circuit. Standard duty applications include a 2-bearing, single shaft design, while 4-bearing dual shafts are manufactured for the most demanding requirements.

Washing Equipment

SUPERIOR - Coarse Material Washer

Built to withstand rugged conditions, our Coarse Material Washer will remove clay, dirt, vegetation, dust, and other rock coatings that cannot be removed by wet screening alone. In aggregates, coarse is usually defined as 3/8” to 3.5” (10 – 80mm). These washing screws also aid in separating fine particles from the coarse aggregates. The combination of water and paddles agitate the material, allowing sand and other small particles to separate and be carried away as slurry. By removing impurities, Coarse Material Screws contribute to the production of high-performance concrete and asphalt mixes.

Conveying Equipment

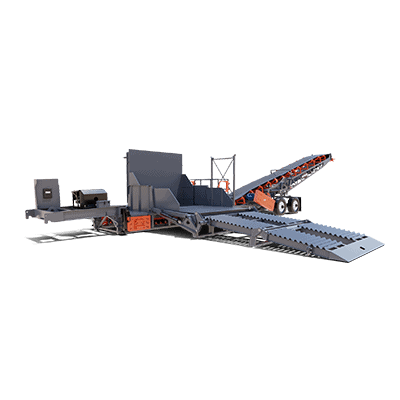

Superior Industries - RazerTail Truck Unloader

Superior Industries' RazerTail Truck Unloader is designed for efficient dry bulk material handling, enabling direct transfer from dump trucks to conveyors, barges, railcars, and other transport systems. By eliminating multiple material handling steps, it helps maintain material integrity and significantly reduces operational costs. The unit is noted for its portability, ease of setup, and operational efficiency, making it suitable for applications such as truck to stacker, truck to barge, truck to ship loader, and truck to railcar transfers. Features include self-cleaning hydraulically-controlled ramps, an inverted hydraulic powerfold system to protect cylinder rods, a wrap drive configuration for better tensioning and reduced spillage, and adjustable height discharge for versatile transfer targets. The entire setup can be positioned and operational within minutes, and the configuration ensures minimal ground contact for materials, enhancing operational cleanliness and efficiency.