Superlit Boru San. A.S products

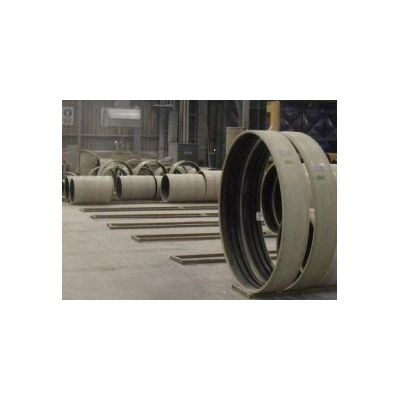

GRP Couplings

GRP Full Face Couplings

Special design internal surface coated with EPDM provides tightness under high pressures. The internal surface of Superlit GRP coupling is coated completely with EPDM material and when compared with the smilar systems, it guarantees safer joining tightness and leak proofing. Superlit GRP Pipes produced by Centrifugal Casting and Continious Filament Winding systems, have the same external diameters. Due to this reason, the same GRP Couplings can be used in the pipes produced both methods.

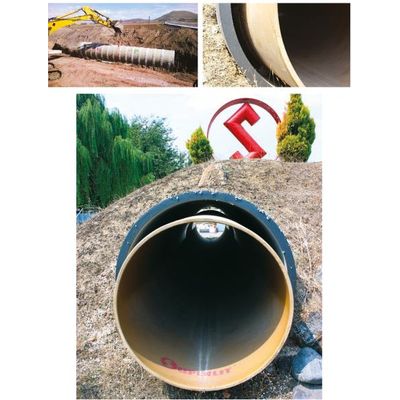

Glassfiber Reinforced Polyester (GRP) Pipes

Although standard lengths are 6 m and 12 m, SUPERLIT GRP pipes can be manufactured with the lengths required, only limited by transportation capabilities. Comprising of thermosetting resin and silica sand reinforced with glass fiber, a GRP pipe is a composite material that has flexible characteristics.

GRP Tank and Water Retention Systems

In addition to pipes used for water supply, SUPERLIT also caters for water storage needs with its GRP tank systems. The GRP tank systems have an important place in the preservation of water in healthy ambient conditions thanks to its mechanical, thermal and chemical equipment. Providing a considerable advantage in transportation thanks to its lightness, the GRP tank systems are preferred not only because it requires no additional installation costs, but also because it minimizes the time required for installation.

GRP Pipe

Superlit - GRP Pipe Systems – Centrifugal Casting

The latest developments in the computer technology are being used in Superlit GRP Pipe production and owing to this, raw material distribution and raw material consumption can be controlled. Theoretic and actual raw material consumption information are reported by the computer. When the desired pipe class and diameter inputs are entered into the computer and a single button is pushed, then the computer will control the process at all the stages until the pipe is pulled out of the mold, thus leaving no room for human errors.

GRP Coupling

GRP Full-Face - GRP Coupling

The inner surfaces of the SUPERLIT full-face® GRP couplings are coated completely by EPDM sealing, which maintains a safer joining tightness when compared with similar systems and ensures water-tightness under high pressure. Since the seal is integrated into the coupling, it does not dislocate and does not require to be installed on the worksite.

Superlit - Full-Face Slip-On GRP Coupling

SUPERLIT FULL-FACE GRP SLIP-ON Coupling ; Developed product as a result of Superlit R&D studies. New designed gasket profile allows sliding of the coupling on both direction over pipe surface, provides a technical solution to the repair of damaged pipe line section and tie-in problems of pipelines with corrosion free GRP composite structure. SUPERLIT FULL-FACE GRP SLIP-ON Couplings are completely covered from inside with EPDM integrated gasket profile bonded in factory condition.

Superlit - GRP Jacking Coupling

New developed GRP jacking coupling is taking place as an alternative to steel joints which are used in trenchless applications. It provides unique solutions to corrosion issue of agressive soil environment where metal couplings have limit of service life under corrosion attack. New composite jacking coupling has minimum 50 years of service life in similar and even higher conditions. Special designed full face rubber profile ensures leak tigthness by help of its GRP structure of body and fully comply with the performance requirements of ISO 25780 standard.

Special Applications

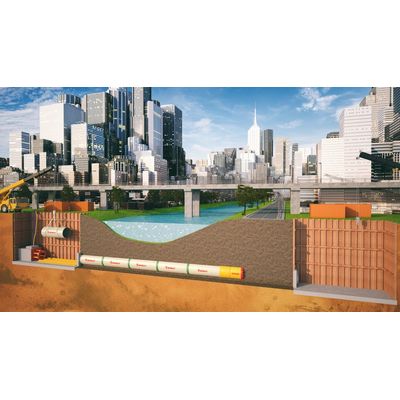

Jacking Pipes

There are no excavations in the jacking pipe installation model. Pipes are installed inside a tunnel underground by using special purpose machines (tunnel boring machine – TBM), by jacking method.

Superlit - Relining Pipes

The relining model also does not require excavation. In order to renew the old pipelines, new GRP pipes are installed by inserting them inside the existing pipes.

Marine Lug - Underwater Pipe Mounting System

Patented special Marine-Lug, which has been designed by SUPERLIT engineers, is an underwater pipe mounting system for installing large diameter pipes.