Syntron Material Handling products

Belt Conveyor Idlers - Tapered Roller Bearing Idlers

Link-Belt - Idler

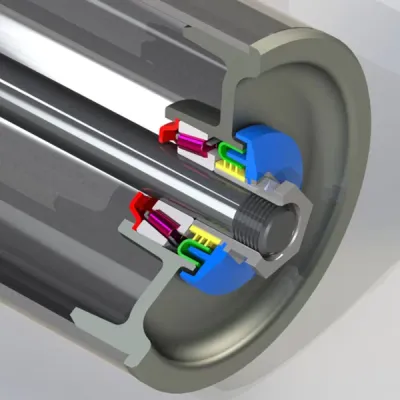

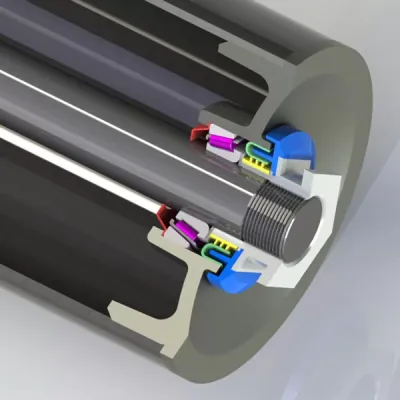

The Link-Belt E4000 series idler line features factory lubricated and sealed-for-life rolls, which eliminate re-lubrication maintenance costs. The E4000 Idler line is also available with lubrication fittings at both ends of the idler for ease in field re-greasing from either side of the conveyor. Boasting load ratings exceeding CEMA E requirements, this idler line is designed for maximum capacity and continuous handling of most abrasive materials.

Bucket Elevators

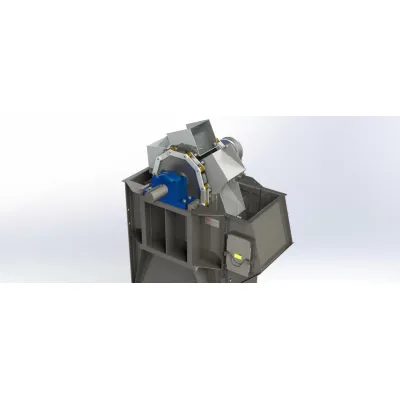

Link-Belt - Engineered Bucket Elevators

The Link-Belt bucket elevators, designed by Syntron Material Handling, are crafted for robust performance and reliability in various bulk handling applications. These elevators come in standard Type 1 and Type 7 models, each offering unique features to effectively manage a wide range of materials. Known for their quality and dependability, Link-Belt elevators are suitable for industries requiring efficient vertical transportation of bulk materials such as grains, minerals, and aggregates. Whether you need to move coarse or fine particulate substances, these elevators provide a dependable solution with customizable options to meet different volume and height requirements. They are designed to ensure smooth operation, reduced maintenance, and long-term durability. Explore additional specifications in the bucket elevator catalog to select the best option tailored to your operational needs.Link-Belt - Buckets for Bulk Material Handling

Link-Belt elevator buckets are engineered to handle bulk materials efficiently in both centrifugal discharge and continuous bucket elevators. Available in diverse types and sizes, these buckets are constructed from materials such as formed steel, ductile iron, Promal, nylon, and polyethylene. Ductile iron is favored in cast buckets due to its resilience against abrasion and stress during digging. Promal offers higher tensile and fatigue strength, as well as better resistance to wear. For handling abrasive materials, ductile iron buckets with Flint-Lip lips offer extended wear life. Buckets are also available in mild, abrasion-resistant, stainless steel, and aluminum. Type AA and MF varieties can be made from nylon or polyethylene, catering to specific handling requirements. Centrifugal Discharge Buckets suit granular, free-flowing materials, while Continuous Buckets handle friable materials with a clean discharge process, optimized for higher capacities at lower speeds.

Heavy-Duty Feeders

Syntron - Electromagnetic Feeders

Syntron® heavy-duty electromagnetic feeders increase bulk handling productivity with controlled high feed rates that improve cost-per-ton handling efficiency. These versatile feeders are capable of handling a variety of materials from the finest powders to large, coarse particles. They are available in ten different models with capacities ranging from 25 to 1600 tons per hour, based on dry sand weighing 100 pounds per cubic foot. Capacities vary depending on drive unit location, material characteristics, material density, trough length and width, trough liner type, feeder installation, skirt boards, and hopper transitions.* Syntron electromagnetic feeders require minimal maintenance, as there are no mechanical parts to wear out such as cams, eccentrics, belts, and bearings, thus eliminating the need for lubrication. All movement is confined to the heavy-duty leaf springs. Electrical components, such as the coil, will provide years of service under normal operating conditions. Dust-tight drive units are standard on all models.