- Home

- Companies

- TANN Corporation

- Products

TANN Corporation products

VOC Control Systems

Tann - Regenerative Thermal Oxidizers

Regenerative thermal oxidizers (RTO’s) are the most common oxidizer in today’s market. RTO’s are capable of extremely high thermal efficiencies up to 97%. When considering a replacement oxidizer, RTO’s can cut the customer’s gas cost considerably making the switch an easy decision. Due to their high thermal efficiency, RTO’s can often go into “self-sustain” mode, in which the burner shuts off completely, using zero gas. Longevity is also another big advantage for the RTO, because the heat exchanger and combustion zone are internally lined with refractory insulation.

Tann - Recuperative Thermal Oxidizers

Recuperative thermal oxidizers use a stainless steel heat exchanger to preheat the incoming process air to within 400°F of the combustion temperature prior to entering the combustion chamber. The burner will provide the remaining energy to heat the process air to the combustion chamber temperature of ~1,400°F. In the combustion chamber, the VOC’s within the process exhaust will convert to CO2 and H2O. This 1,400°F air, now clean, will pass through the opposite side of the heat exchanger, thus providing the energy for the incoming process air. Most recuperative oxidizers will utilize a shell and tube style heat exchanger. The shell and tube design will provide a longer life and provide access for cleaning if needed. Recuperative heat exchangers can have thermal efficiencies from 40% to 80% depending on the application.

Tann - Catalytic Thermal Oxidizers

Catalytic oxidizers use a catalyst to reduce the oxidation temperature. Unlike the 1,400F operating temperature of a thermal oxidizer, a catalytic oxidizer can operate at much lower temperatures such as 600-700F. This lower operating temperature can reduce the operating costs and prove to be the most efficient solution. Catalytic oxidizers can be either direct (no heat exchanger), recuperative, or regenerative.

Tann - Direct Oxidizers

Direct oxidizers use a burner to preheat the incoming process air prior to entering the combustion chamber. The burner will provide enough energy to heat the process air to the combustion chamber temperature of ~1,400°F. In the combustion chamber, the VOC’s within the process exhaust will convert to CO2 and H2O. This 1,400°F air, now clean, will exhaust to the atmosphere. Direct thermal oxidizers can be designed in a vertical position or horizontal. Raw gas burners are common to reduce the overall energy consumption. A direct thermal oxidizer can be a low-cost solution for many applications.

Other Products

Tann - Ductwork Pipe

At TANN Corporation, we can engineer, design and manufacture any ductwork job to meet your needs, with diameters ranging from six to 110 inches. We can fully weld your ductwork for the toughest applications and design them to withstand corrosive or high-temperature environments.Our ductwork can be fabricated from stainless steel and can be internally insulated. Our expansion joints are steel bellows fabricated from carbon steel or stainless steel.

Tann - Dampers

TANN will design and build custom dampers for your process needs. Our engineers will determine the correct damper for each application. Dampers can be built with or without gaskets, include proof of closure switches, or insulated for higher temperature applications.

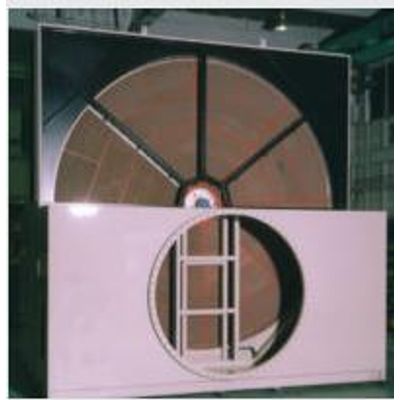

Ta - Concentrator System

A TANN concentrator is ideal for most process exhausts with a high volume and a low concentration of volatile organic compounds (VOCs) at a low temperature. The design we use can handle up to a 20:1 concentration ratio and up to 95% relative humidity. Concentrators work by sending process air through a large section of the continuously rotating zeolite wheel where 90-97% of VOCs are adsorbed. Once the VOCs are removed, the air passes through the wheel and is sent to atmosphere. A warm air stream passes counter-current through a smaller section of the concentrator where the VOCs are stripped off the wheel. This ‘desorption zone’ cleans the wheel and creates a low volume/high concentration exhaust to feed an oxidizer.