Taylormade Renewables Ltd. products

Taylormade TRL-RAIN - 50 KLD Plant

RL-RAIN is a patented technology low temperature application developed for evaporation and condensation from any kind of Saline, Brackish, Mine waste water, RO Reject, Chemical induced water, Waste Water produced from various industries like Oil & Gas, Textiles & Tanneries, Power Generation, Mining & Metals, Refining & Chemicals, Food & Beverages, Pharmaceuticals and many others

Taylormade TRL-RAIN - Patented Solvent Recovery System

The TRL-RAIN ULTRA patented solvent recovery system is one of the most innovative technology. The system can yield maximal solvent as a product at a very low cost due to the unique design of the evaporator and condenser, and this without the usage of vacuum pumps or chilling towers. For the solvent recovery process, the TRL-RAIN ULTRA SRS does not require any columns for evaporation or condensation. The new technology of the solvent recovery system is simple to install and run, with improved energy efficiency and does not require any CIP.

Taylormade - Super Distillation Unit (SDU)

The most commonly used techniques are simple distillation, fractional distillation, steam distillation, and vacuum distillation. In simple distillation process, a volatile compound is evaporated and channeled through a distillation column into a condenser, where it is eventually captured. TRL – SDU is a new method of distillation, wherein water can be distilled at 48º C, which means many of the solvents can be evaporated and Condensed at ambient temperatures. The heat sensitive materials are easily recovered without charring or decomposing with TRL-SDU. TRL-SDU, is a novel technology which does not use any Vacuum Pumps, Chillers and it’s a closed loop system making the Environment 100% safe. Cost of distillation is most economical (more than three times) compared to any other distillation technology in the World.

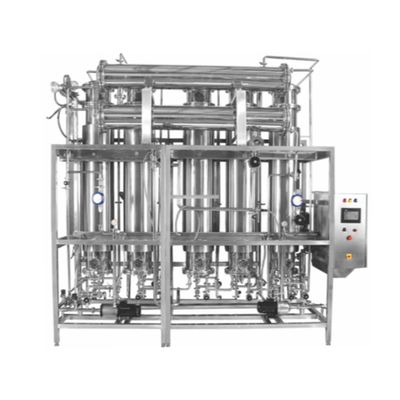

Taylormade - Distilled Water Plants (DWP)

The most commonly used techniques for water distillation plants are simple distillation or Falling film distillation followed with columns. TRL – DWP is a new method of distillation, wherein water can be distilled at 48º C, which means none of the salts carry to condenser unit. The TDS levels are less than 10 ppm or non measurable levels, if needed it can be further reduced by convectional methods. TRL- DWP can have applications in Injectables, Pharma applications, Battery manufacturing and many more. TRL- DWP, is a novel technology, which does not use any Vacuum Pumps, Chillers and it’s a closed loop system making the Environment 100% safe. Cost of distillation is most economical (more than three times) compared to any other distillation technology in the World.

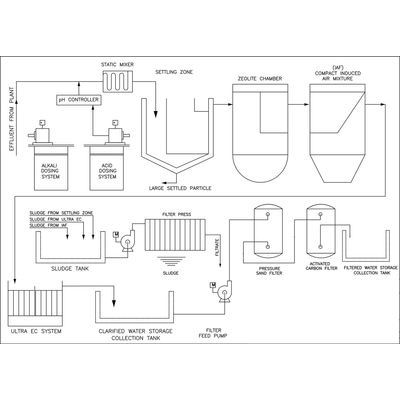

Taylormade - Waste Water Treatment System

TRL IAF EC-ULTRA is a Patented Waste water treatment application developed for Grey Water, Hospital waste water, Sewage water, Brackish water, Mine waste water, Chemical induced water, Waste Water produced from various industries like Oil & Gas, Textiles & Tanneries, Power Generation, Mining & Metals, Refining & Chemicals, Food & Beverages, Fertilizers, Pharmaceuticals and many others. Best and most economical solution for surface and sub-surface disposal from Oil & Gas Produced waste water. For sub-surface disposal the cost of water can be lower than Rs. 10.00 per KLD or M? (Larger the size lowers the cost). For surface disposal the cost is less than Rs. 40.00 per KLD or M?, which is the lowest by any existing technology in the World. The cost mainly depends upon the impurities in the water which is to be treated with minor modifications in the treatment Process.