- Home

- Companies

- Techno Designs

- Products

Techno Designs products

Process Products - Solids Storage

Techno - Storage Silo Systems

Our Silos are designed, fabricated, delivered and commissioned in an extensive range of applications. Every silo is developed according to the customer`s unique requirements and constraints. Depending on how the silo is to be employed into the system, we provide storage, mixing and blending solutions.

Process Products - Solids Processing - Air Classifier

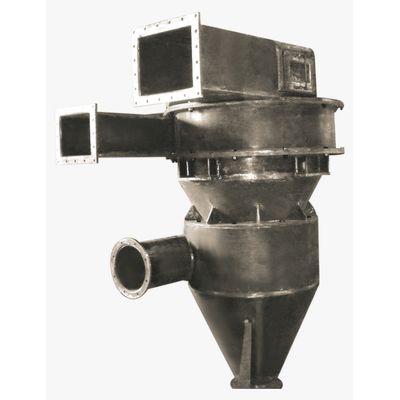

Techno - Model VWC Series - Air Classifier

We are the manufacturers of the VWC classifiers that are efficient dynamic air classifiers with a vertical classification rotor. They are suitable for classifying material between 15 to 80 microns material. Operating with a low pressure drop makes these classifiers very economical in operation. Fewer parts in the classifier means this classifier is economical in terms of the initial investment as well. Adjustability of the secondary air stream and the rotor speed allows for a precise onstream control of the sharp cut-point, which allows you to obtain the particle size desired.

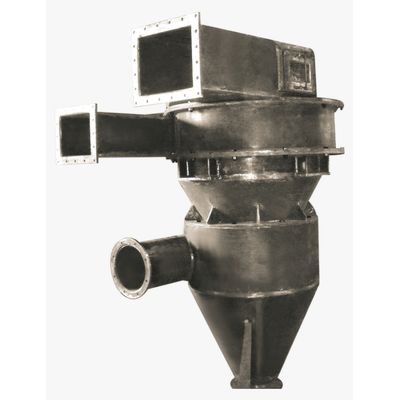

Techno - Model MWC Series - Air Classifier

The MWC series manufactured by us consists of versatile and highly capable classifiers. These classifiers are capable of fulfilling the need for super-fine cut sizes at high throughput rates.

Process Products - Solids Processing - Ball Mills

Techno - Continuous Ball Mill

We are a leading ball mill manufacturer, exporter when it comes to continuous ball mills. Our commitment to quality is the main reason why we deliver world-class continuous ball mills. Our stainless steel ball mills are used to grind ores and minerals from a feed size of 6mm and Moh`s hardness upto 5 to d97

Techno - Batch Ball Mill

Techno Designs delivers batch ball mills that can be used in a variety of applications such as paints, pigments, and other industries. Our specialized Batch ball mills are known to have the lowest maintenance times, a fact that makes them a success with respect to quality. We accessorize our batch ball mills with feed and discharge nozzles that aid in raw material loading and unloading of the final product. We add flexibility and versatility to our mills by delivering add-ons like cooling jackets for the shell, bearings, and features of auto-lubrication.

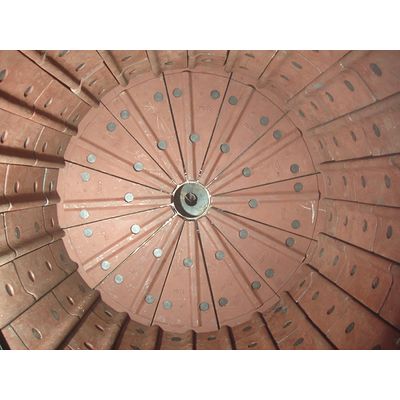

Process Products - Solids Processing - Pin Mill

Pin Mill

Techno Designs has worked in the field of comminution for over 20 years and our pin mills have been developed based on such extensive experience in particle processing. Our Pin Mills can be universally used for grinding a variety ofmaterials. Pin Mills are used in minerals, food, chemicals, plastics and the pharmaceutical industry. Material in a Pin Mill is fed in a centrifugal manner, and is gradually ground to finer sizes by impact crushing of the rows of pins. Depending on the product type, a fineness of 25 to 30µm can be achieved. Our counter-rotating pins provide excellent grinding results at much more economical costs.

Process Products - Solids Handling

Techno - Rotary Airlock Valve

Techno Designs is a leading Rotary Valve manufacturer India, and we also specialize in manufacturing and supplying Rotary Airlock Valve India. Our standout quality rotary valves are sturdy and long-lasting. We cater to a number of leading industries as their Rotary Valve manufacturer India such as-

Techno - Dual Tunnel Diverter Valve

Techno design`s dual tunnel type diverter valves are designed to solve the purpose of routing powders and pellets in pneumatic conveying systems. We design dual tunnel diverter valves for minimum degradation of the material. The diverter valves are immensely useful in the pharmaceutical, chemical, plastic, and food manufacturing industries, along with others. The diverters are known so as they divert solids flowing in a dense phase and those flowing in a lean phase to multiple different destinations. The minerals industry, the agricultural sector and other solids handling systems also require these dual tunnel diverters.

Techno - Gravity Diverter Valve

Gravity Diverter Valves are employed for dry powder gravity flow applications for dosing and discharge purposes. Unique design with a blade pocket protects the leading edge of the blade from wear, which prevents leakage of the powdered material. Easy access is also provided with an inspection window available as an option.