- Home

- Companies

- TEHAG GmbH

- Products

TEHAG GmbH products

TEHAG - Particulate Filter System

Extremely versatile and practical particulate filter system. Purely passive regeneration for exhaust temperatures from 230 °C (10 to 1 5 % load) without additional energy demand, control or additives. Very little space required both for original equipment und retrofitting. VERT* / LRV conformity, ABE, RDW certification and TR6S 554-compliant. Retrofitting subsidised by B6 Bau (DE). A reduction in particulate matter of > 99 %. Reduction of hydrocarbons (HC) and carbon monoxide (CO), at times below the limit of detection. Controlled monitoring of exhaust temperatures and counter pressure.

TEHAG - Particulate Filter System

The »Active Wall-Flow HC-dosing« (AWF h) ) Particulate Filter System is a solution for vehicles and machinery that require low load profiles due to their areas of application and in which the exhaust temperatures repeatedly drop below the critical limits for purely passive regeneration. Depending on the vehicle or machinery application, the system automatically starts regeneration of the particulate filter when the counterpressure exceeds a freely programmable value. During regeneration, the diesel is injected into the exhaust gas, which increases the temperature in the filter to around 600 °C. At these temperatures, the carbon contained in the filtered particulate matter reacts with the residual oxygen in the exhaust. This allows regeneration to work independently from the vehicle/machinery application, effectively eliminating downtime.

TEHAG - Particulate Filter System

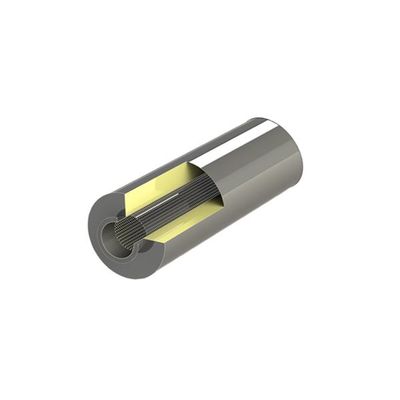

With the »Active Wall-Flow-electrics« (AWF-e) Particulate Filter System, we offer you a versatile particulate filter system for machinery and systems that are operated regularly at a fixed location or within a limited deployment radius or for limited periods of time. These include lifting platforms, municipal vehicles and industrial trucks, as well as stationary power generators. The filtered particulate is regenerated using a heating coil that is integrated into the system’s inlet hood upstream of the filter element. The system is connected to an external power supply at the end of a shift, after deployment for a limited period of time, or when the filter monitoring system shows a corresponding message on the display. Once the system is connected to the mains, the regeneration process can be started.

TEHAG - Selective Catalytic Reduction (SCR) System

At a Glance: Tried-and-tested technology for the reduction of NOx in exhaust. Can be installed on mobile machines, vehicles, rail vehicles, ship engines and stationary systems. Suitable for diesel, petrol and natural gas engines, both mobile and stationary. Automatic control and function monitoring. High reduction rate of NO and NO2. T-blue NOx available both for original equipment and retrofitting.

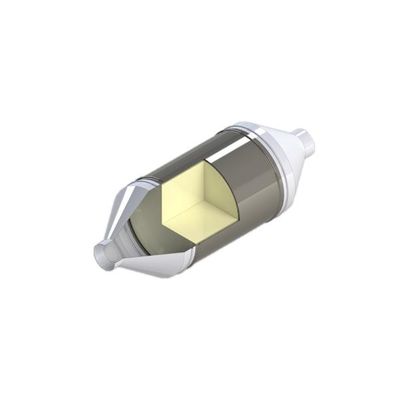

TEHAG - Oxidation Catalytic Converters for Diesel, Petrol and Natural Gas Engines

At a Glance: Powerful oxidation catalytic converters for the reduction of carbon monoxide, hydrocarbons, methane and formaldehyde. Solutions for diesel and natural gas engines in all performance classes. Suitable for mobile and stationary engines. Tailored coating compositions. Available with ceramic or metallic cores. Designs can be tailored based on the installation space available as well as individual requirements. Oxidation catalytic converters for combined heat and power plants (CHP plants), generators and drive motors.

TEHAG - Filter Monitoring Systems

The PTL filter monitoring is especially developed for constant function monitoring of diesel particulate filter systems. The electronical device measures the exhaust temperature as well as the back pressure ahead of the filter. To suit each vehicle type and effort, additional a measuring probe for recording the number of revolutions can be connected. By the default option the displaying of the operating states take place via a three-tone LED, which is installed in the cockpit of the vehicle or rather engine. Possible malfunctions as well as the load status of the particulate filter are able to be recognized immediately and can be eliminated by the driver if necessary.

TEHAG - Industrial Silencers

The optimal solution for silencing in every application. At A Glance: TENOR Industrial Silencers for nearly every application: on-road, off-road, maritime and stationary. Absorption, reflection and combined silencers for natural gas, diesel and petrol engines. Compliance with standards in terms of noise level dB(A) and exhaust counterpressure (mbar) through design and calculation. Optimised construction and size as well as sequencing in and integration into the exhaust gas system. Production capacities for small and medium series. High-quality products, short delivery times, flexibility and personal support.