- Home

- Companies

- Tenco Hydro, Inc.

- Products

Tenco Hydro, Inc. products

Tenco Hydro Clari-Float - Dissolved Air Flotation

Tenco Hydro Clari-Float provides high performance by the use of proprietary design features to maximize DAF performance. These include a proprietary inlet chamber and recycle pressurization system. The inlet chamber dissipates energy and turbulence from the mixing of feed and depressurizing flows. It is then transformed to an evenly distributed laminar flow as it enters the DAF cell. Additionally, any excess (undissolved) air is captured and vented outside of the DAF cell, thus preventing air turbulence and disruption of the floated sludge at the surface. This results in optimum use of the DAF cell flotation area.

Tenco Hydro Clari-Scum - Scum Grease Concentrator

The Clari-Scum grease used to capture and concentrate grease and other naturally floatable material. The concentrator is sized to accommodate the rise rate of the floatable material and to allow adequate residence time for capture to occur. Operating features include On-Off timer or variable skimming rate to allow the layer of floated grease to drain interstitial water, resulting in a thicker concentrate. Along with an adjustable overflow weir, this gives operators the option to dial in the desired grease concentration needed to suit plant operations.

Tenco Hydro Thermix - Heated Wastewater Tank

Some municipal wastewater treatment plants find beneficial use for the concentrated scum / grease. Grease contains considerable heat value. When used as a supplemental heat source for incineration or for further processing by a digester, it is desirable to further reduce the water content. The Tenco Hydro Thermix Heated Batch Process Tank System does this and provides other benefits such as heating and blending to a more homogeneous liquid that is easier to pump.

Tenco Hydro - Coalescing Oil Water Separator

The Tenco Hydro Clari-Pac C is used to separate free floating oil in wastewater. The influent energy is dissipated and evenly distributed as it enters the coalescing chamber, where coalescing media produces a weaving flow pattern to promote contact and coalescence of smaller oil globules into larger sizes. The increased rise rate due to the larger globule size optimizes separation efficiency. Clari-Pac C sizing is determined by using the applicable rise rate for the oil globule size, and other guidelines per the American Petroleum Institute (API) Publication #421. The result is excellent oil removal in a smaller footprint than is needed for basic gravity separation.

Tenco Hydro - Gravity Oil Separator

The traditional process for separation of free oil in wastewater is the use of a gravity separator designed per guidelines and recommendations of the American Petroleum Institute (API), publication #421. Flow distribution, surface loading rate (rise rate), tank geometry, effective surface oil removal are some of the important design considerations in Tenco Hydro`s API gravity oil separator. Oil characteristics such as specific gravity, viscosity and temperature are applied to Stoke`s Law to determine the design rise rate for capture of oil globules 150 microns or larger. Separator size is determined by influent flow rate and rise rate. Tank proportions and flow distribution are per API guidelines.

Tenco Hydro Skim Kleen - Belt Oil Skimmer

The Tenco Hydro Skim Kleen belt oil skimmer is an effective way to remove accumulated free-floating oils from places such as process tanks, sumps or manholes. Skim Kleen has proven to be effective, durable, and reliable over many years of operation both indoors and outdoors. The concept is simple. An endless belt is drawn through the accumulated oil on the water surface. Oil adheres to the belt and is carried up to the skimmer where it is doctored off the belt into a trough, and gravity discharged. The heavy duty Skim Kleen features stainless steel construction throughout. Belt material, width and length are selected for oil adherence and material compatibility.

Tenco Hydro - Clarifier Used for Gravity Separation

Clari-Pac G clarifiers are used for gravity separation of settlable solids in wastewater where space is at a premium or is the process equipment of choice. Whether known as inclined plate clarifiers, plate settlers or tube settlers, a Clari-Pac G clarifier multiplies (stacks) its smaller footprint to provide the necessary surface area to satisfy the required surface loading rate (settling rate) for effective solids separation. Inclined stacked plates or tubes are used commonly for this purpose. With an angle of inclination of about 60 degrees, settled solids are automatically sloughed off and are collected in a hopper shaped trough below. Influent feed flow is distributed upwards and uniformly through the media in a counter-current pattern.

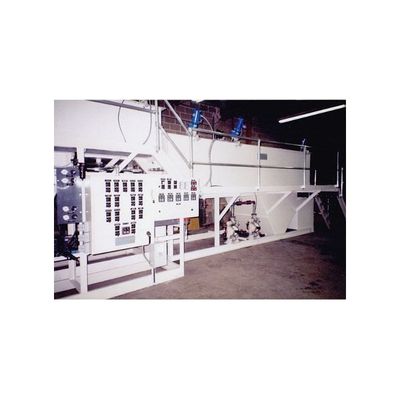

Tenco Hydro - Filtration Process System

As required by system responsibilities, Tenco Hydro has designed and supplied other process equipment, in addition to our standard products, to meet the desired or specified discharge limits of the specific application. Tenco utilizes a preassembled, skid mounted, modularized approach for efficient field assembly. Other process equipment includes pumps, mixers, process tanks, pH neutralization, chemical addition systems, mixed media filters, activated carbon treatment, organoclay adsorbtion, membrane filters, sludge handling and solids dewatering. Specialized controls and instrumentation are also commonly incorporated. Individual process equipment is also offered.