- Home

- Companies

- The Rubber Company

- Products

The Rubber Company products

Gaskets & Seals - Rubber Gate Seals

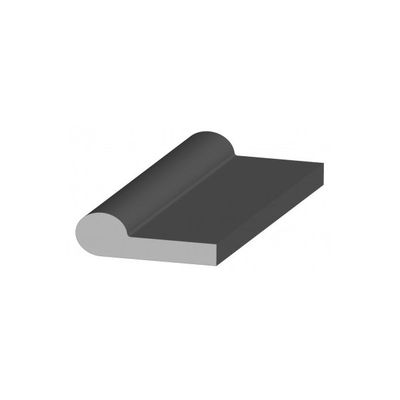

Gate Seal

Our P seals or “music note seals” as they are also known, are available in two different formats. Depending on the load deflection criteria we may suggest either a solid or hollow bulb. The hollow bulb format is more suitable for use in low hydrostatic pressures. While the solid bulb format is less prone to compression. When under pressure, either the bulb or stem can create a seal. Bulb deflection is appropriate for seals which are in high compression load applications. Whereas, stem deflection is more appropriate for use in; low compression loads, sealing irregular surfaces and large tolerances in the gate dimensions.

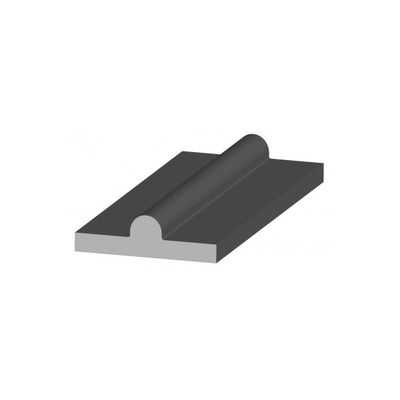

Double Gate Seal

Our double P gate seals provide many of the same sealing properties found in our standard P gate seals. The main difference between the two, is that our double p seals enable you to seal against two surfaces using a single profile. The bulbs can compress under pressure in order to create a watertight seal. Double P gate seals typically secured and bolted through the stem to provide bulb deflection. These seals are typically installed to a plate and then pressed against a sealing face. This ensures that the profile provides consistent sealing capabilities regardless of water pressure.

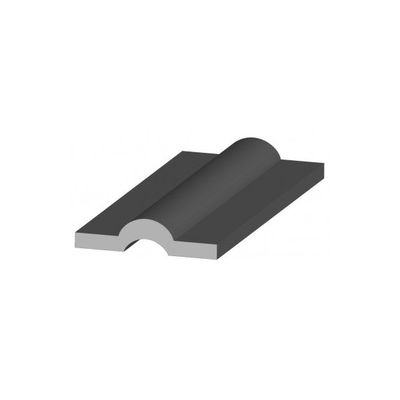

Hump Gate Seal

We can manufacture our hump gate seals in two standard formats. Either with a single or double hump depending on the application. Hump seals are generally used for sealing the top edge of submerged vertucal-lift gates. Our hump seal are typically bolted either side of the hump or the flat stem section of the profile. The hump section is then pressed against the sealing surface. The flexibility of our hump profiles enables them to compress slightly when pressed against the sealing surface. This ensures that the profile is able to form a watertight seal regardless of the water flow and pressure.

Double Hump Gate Seal

Similar to our hump seal profiles our double hump seal profiles create a seal using compression under pressure. Our double hump seals are often commonly used on tidal river gates. The dual humps can protect from water either side of the channel, similar to our double P seals.

Omega Gate Seal

Our omega gate seals are often used to create an internal seal between two surfaces on underwater tunnels. These seals generally perform as a membrane as they are exposed to three dimensional movements between the tunnel sections. Omega seals can also be reinforced with fabric in order to enhance the seal with additional mechanical properties. We can increase or decrease the number of fabric layers in order to suit the maximum hydrostatic pressure and required safety factor. We can also manufacture our omega gate seals with a series of small ridges on the sealing face. This will ensure that the profile is able to create a watertight seal under a variety of pressures.

Extrusions & Profiles

Expansion Seals & Joint Fillers

Expansion seals or expansion joints as they are also known, provide a subtle yet crucial function in a wide variety of construction applications. The key purpose of an expansion seal is to provide a flexible connection point between two concrete, cement or similar structures. We specifically manufacture our TPE expansion seal profiles to provide excellent abrasion as well as impact resistance. This enables our expansion seals to provide a superior life expectancy compared to similar alternatives.

Facade Rubber Seals

The Rubber Company can provide an extensive range of rubber glazing seals, weather seals as well as fixing profiles for a number of applications. Our facade rubber seals are suitable for use in a wide range of applications and environments. We have a wide selection of facade seals available as standard, with quick lead times. We can also manufacture bespoke gaskets, seals and pads to match your exact requirements, subject to minimum order quantities.

Matting, Flooring & Decking - Diamond Matting

Diamond - Top PVC Matting

Our diamond top PVC matting is a cost efficient and highly versatile flooring solution. The diamond pattern on the top surface of this matting provides a superb anti-slip surface. This enables you to use our matting with a variety of footwear types in dry as well as wet environments. The diamond finish also serves to create an effective anti-fatigue working surface. This helps to reduce stress and strain on joints while maintaining concentration over a long period.

Diamond - Tough Comfort Matting

Our diamond tough comfort matting combines excellent underfoot comfort with a heavy duty, hard wearing top surface. This is the only matting to offer comfort and protection for use in hard wearing industrial applications. The diamond pattern on the top surface also serves to increase the anti-slip properties of the matting. This enables our matting to provide additional safety for all footwear types in dry working environments. We supply our mats in a variety of sizes from 60cm x 90cm to 1.2m x 23m as standard. Our matting is also available in either black or black with a high visibility yellow strip.