Throop Rock Bit products

Junk Mills

Twister - Junk Mills

The Twister is designed to run with traditional jet-type fluid flow, in a work-over application, drilling cement, cast iron bridge plugs, retaining rings and difficult to drill applications. The Twister features five jet type ports for high pressure fluid flow to break up and clean the bottom of the hole.

Raptor - Carbide Cutters

The Raptor features the largest carbide cutters in the industry for drilling further and faster. Specifically designed to be run in a reverse circulation work-over application, drilling junk, cement, cast-iron bridge plugs and retaining rings. The Raptor features three large circulation ports coupled with three deep cleanout slots to provide maximum cuttings for faster ROP and longer bit life.

Completion Bits

Throop - Model FPM511 - Frac Mill

Durable and stable, the Throop Frac Mill FPM511 is specifically designed to efficiently engage and mill up long strings of composite frac plugs set inside of production wellbores. Featuring a ballistic profile and a balanced PDC cutting structure that concurrently provides toughness and ROP, The FPM511 generates small and consistent cuttings, plug after plug.

Throop Rock - Sealed Friction Bearing Bits

The family of Throop sealed friction bearing bits, includes both slimhole and standard TCI & Mill tooth tricone drill bits has gained significant field experience over the last decade, making our bits a trusted choice amongst industry professionals worldwide. Throop`s generation two bearing package, featuring silver plated thrust washers and bushings, proprietary seal compounds, specially formulated bearing lubricant, and robust grease compensation system come standard on each product.

HDD Bits

Patriot - HDD Bits

Durable, stable and steerable, the Patriot can be effectively utilized in a wide range of drilling applications. Featuring a balanced PDC cutting structure that concurrently provides toughness and ROP, the Patriot also delivers smooth drilling response for effective directional control.

Throop Rock - Model TR2, TR1 and TR1H - Workover Bits

Throop`s open bearing steel tooth bits for re-entry, remedial, and water well applications. All bits are available in full center hole and can do either regular or reverse circulation which is frequently used to re-enter wells. TR2, TR1, and TR1H are offered from softest to hardest of the cutting structure applications.

Workover Bits

Badger - Workover Bits

The Badger is specifically designed to be run in a reverse circulation work-over application, drilling junk, cement, cast-iron bridge plugs and retaining rings. The Badger features three large circulation ports that provide maximum fluid flow.

Throop Rock - Model R4 Series - Workover Bits

Throop Rock Bit`s R4 model is specifically designed for reverse circulation mineral exploration. It features an enlarged center hole to facilitate the removal of materials being drilled. A step design is included on the shoulder to fit existing drill systems and extra machining on the sides to allow material to pass through to the central hole without plugging or clogging. Featured in a wide variety of chisel, conical and dome inserts.

Fixed Cutter Bits

Eliminator - Fixed Cutter Bits

The Eliminator features a concave cutting head specifically designed for centering the drilling surface and drilling the outside perimeter of the hole first. The bit hydraulics incorporate five fluid ports to flush cuttings. Application: Workover, completion & junk milling.

TCI Bits

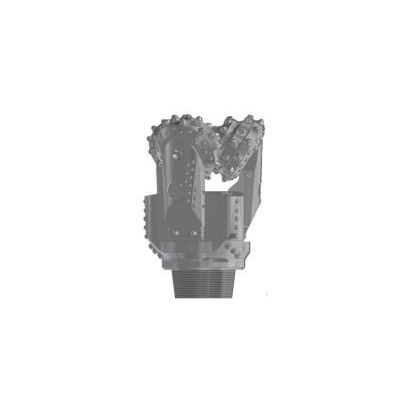

Sealed Roller Bearing TCI Tricone Bit

Throop Rock Bit Sealed Roller Bearing tricone bits are equipped with a lubrication and compensator system to control and stop grease from leaking into the bearing. This system makes it easier for the tricone bit to drill deeper into the formation without the need to be pulled up as frequently as open bearing tricone bits. Our Sealed Roller Bearing tricones are an obvious choice for deeper drilling projects where the cost in time to stop and clear debris is unacceptable. IADC 6-2-7 shown - All formations and circulations available. For more info contact our sales teams: sales@throoprockbit.com