Tip Top Oberflachenschutz Elbe Gmbh products

Coating

Water Pollution Control Coating

Nowadays, water pollution control is of great importance in industrial production processes. The German Water Management Act (Wasserhaushaltsgesetz, WHG) requires that sustainable, long-term protection against chemicals and water-polluting substances must be in place for ground water and bodies of water. Being an experienced specialist firm, TIP TOP Elbe is well aware of its responsibility in this respect. That is why you can rely on us as your qualified partner for the planning and implementation of necessary construction projects. We accompany you throughout the approval procedure, give recommendations regarding the choice of materials and guarantee high-quality application by our professional technicians.

Steel Hydraulics Construction Coating

Corrosion protection in steel hydraulics construction is becoming more and more important. Steel hydraulics construction like water turbines, penstocks, cooling water pipes, pumps, ship hoists, watergates, sheet pile walls, or offshore facilities have to withstand a high amount of corrosive influences as well as mechanical stress. Coating systems and their application have to meet high standards, in particular in the maritime sector. TIP TOP Elbe`s high-quality coating systems fulfil the requirements for corrosion protection class lm1 to lm5 in accordance with EN ISO 12944. The COROPUR NON ABRASIV system has been approved by the BAW (Bundesanstalt für Wasserbau, Federal Waterways Engineering and Research Institute) for application in environments with a high level of mechanical stress.

Acid Protection

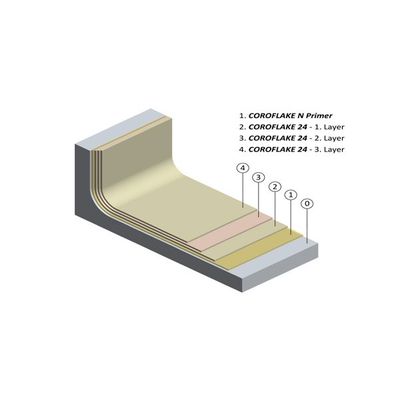

Coating Systems

Our different sealing systems for industrial flooring and walls are made to match the specific requirements and application purposes. We use trowelling, levelling, and laminate coatings, coatings which can be applied by paintbrush, and spray coatings. The coatings we use are based on epoxy, vinylester, furan, and phenol resin and on polyurethane.

Tiling System

Permanent protection through combination coatings in accordance with EN 14879-6 and AGI worksheet S10. In order to ensure long-term protection even in environments with high levels of chemical, thermal, and mechanical exposure, we count on combination coatings which consist of a sealing layer and acid-resistant tiling. These tiles can consist of acid-proof ceramics or porcelain stoneware and can have a rectangular or hexagonal shape. Installation formed by vibration which consist of hexagonal porcelain stoneware tiles with narrow joints are used in settings with particularly high surface requirements, e. g. in the pharmaceutical industry. Tiling can be supplied in electrically conductive form by using a conductive grout.

Plastics Construction

Wastewater Systems

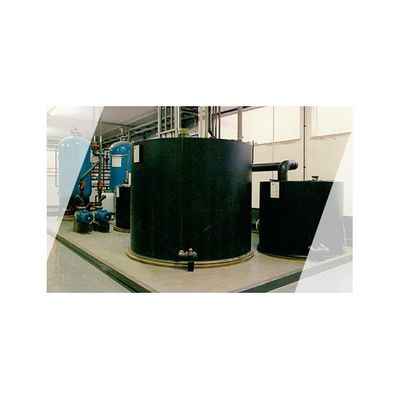

TIP TOP Elbe is also a leading supplier in the field of wastewater treatment. We are pleased to assist you in the planning, project development and support of approval procedures, construction and installation, starting-up and maintenance. Of course, we are also ready to assist in selected areas of this extensive range of services, depending on your needs. For rinsing technology calculations and plant dimensioning, we also work with external specialists.

Ion Exchange Plants

Our individually manufactured ion exchange plants are a perfect way to reduce water consumption and the volume of wastewater.

Rubber Lining

On-Site Rubber Lining

TIP TOP Elbe has developed rubber linings for all industrial sectors. The rubber linings can be used on site regardless of the component size. Our on-site rubber linings offer superior protection for storage vessels, pipelines, reaction vessels, flue gas scrubbers, but also for concrete components like septic tanks, deionising and neutralisation basins. TIP TOP Elbe’s on-site rubber linings are not only an excellent choice for the protection against chemical exposure to acids,alkalis, and saline solutions, which become even more potent with increasing temperatures and temperature change, but also against mechanical stress.

Workshop Rubber Linings

Workshop rubber linings offer excellent protection for components which fit inside an autoclave and can be transported, such as pipelines, flue gas scrubbers, quenching towers, venturi scrubbers, filter cases, storage vessels, reaction and pickling lines, centrifuges, road and railway tanks, containers, pumps and fittings, and rollers and rums. TIP TOP Elbe workshop rubber linings are not only an excellent choice for the protection against chemical exposure to acids, alkalis, and saline solutions, which become even more potent with increasing temperatures and temperature change, but also against mechanical stress. TIP TOP Elbe has developed an extensive range of products in the field of workshop rubber linings. This range is the foundation for the individual choice of rubber qualities.

Brick Lining

Coatings for Floorings, Collection Pits and Channels

Brick lining is frequently used for floorings, collection pits and channels. Wherever high temperatures, extreme chemical exposure or mechanical or abrasive stress are present, TIP TOP Elbe`s brick linings are the perfect solution. The carefully coordinated sealing layer and brick layer form a combined structure which is extremely resistant to corrosion and wear.

TIP TOP Elbe - Vessels Lining

Whether you would merely like to enter your absorber with cleaning equipment to remove gypsum deposits, or operate a quench with 700 °C flue gas inlet, whether you would like to use a reactor vessel with a high solids content for a long time, or plan a sulphuric acid drying tower with a domed grit – we are ready to offer an individually adapted solution combining rubber lining, coating and TIP TOP Elbe brick lining. In addition to protection against thermal and mechanical stress, brick linings offer a higher level of chemical resistance as they prevent direct contact between the medium and the sealing layer.