- Home

- Companies

- TIRES S.p.A.

- Products

TIRES S.p.A. products

Recycling Plants

TIRES - Steel Bead Heel Extraction Phase Machine

The steel bead hell extraction of the truck pneumatic is a fundamental phase, before of its entry in the automatized plant. The machine is principally constituted of two oil-dynamic pistons, which opposed do the extraction from the rim zone of two toroidal rings. These are composed of harmonic steel filaments with a thickness of 1.5/2.5 mm that make a bead with an apparent diameter of 20 mm. Upon the machine has been installed an equipment to avert the break of the garter spring; a precaution planned and realized from TIRES SpA , which put an end to a serious working problem. Actually, the common stallonators suffer the break of the garter spring with a frequency of 1/5, without assuring productivity of the machine and making impossible the final steel bead heel extraction of the tyre. The machine has automation through PLC with joystick push-button board, which control simultaneously all the working parameters, assuring the total success.

TIRES - Shredder Phase Machine

Our plant owns two oil-dynamic rotors triturating for the automatic pre-working. The two machines are installed with a closed circuit through a screening system, from which comes a minimum size of 60x60 mm with a medium hour production of 2500 kg/h. On the machines are installed interchangeable blades and that you can sharpen of nickel material, thermally treated, which assures a long working period. The oil-dynamic working keeps in perfect conditions all the rotation group, besides to give energy saving during the surging of the load. The whole is managed by a automatic board, which controls all the working parameters, assuring productive yield and constant final quality. Today, it is surely the most reliable working system both under the energy side and under the side of the safety.

TIRES - Granulating Phase Machine

The machine has been built considering the smallest details and working criterions. Besides obtaining the patent on year 2000, it has an excellent reliability since several years, in our realized plants. The granulating phase is made by a mono-rotor granulator, having a selection grate into the cutting chamber. The most important characteristics are a grate working on 180º of the rotor and the double cutting system, which increase the productivity of the machine. At the moment, it is the only granulator for tyre granules, which has a grate with a such radius with an oil-dynamic extraction system, compared to 120º up till now reached. Thanks to the experience gained since years, few modification were made to the cutting group giving to eliminate or to decrease the wear found till 20.000 working hours.

TIRES - Refining Phase Machine

In this phase, it is developed the work establishing the quality of the first finished product. Since years, monitoring the scenery of the granules, we have realized a textile cutting and separation system, which find the largest international market. The mechanic has been treated in the details assuring a long duration, today higher than 30.000 working hours. The machine is able to get mixed granules of truck and car, or single type with a diameter smaller than 15/18 mm and to make the textile fibres grinding and separation according to the utilized grate.

TIRES - Pulverization phase Machine

With the pulverization plant we wanted realized a product with accurate mechanical physics characteristics. The rubber pulverization is it a matter where it needs of real methodology, it is today the most efficient and most profitable phase, both under the productive side and the economic one. The productive side because it has studied and realized after more than “120.000 tons” of experience of production; the economic side because the remuneration of the final product is really different compared to the granules. Despite of the marketing applications are fewer and more professional than the market of the granules, the applications in the future surely will stand out it because of the lack of raw material in the compound industry. Our pulverization plant was patented in the year 2000 and has an excellent reliability. All the working process is electronically controlled by programmed automation, so that quality and productivity are constant.

TIRES - Synthetic Carpets Disposal Plant

Since the year 2001, got under way exponentially the using of artificial grass carpets for sports recreational structures. With the passing of the years, the industrial technologies for the building of carpets, have developed up to bring the sports sector to a radical change. The support of the Italian National League of Amateur and the requests of the sports companies to obtain more efficiency on the soccer fields, have contributed to the realization of a lot of artificial sport plants. Italy has been one of the first European nations to install this new methodology but today the use is worldwide. Everyone know by now the benefits that the artificial carpets have, but nobody has thought of finding a 100% ecological solution at the end of their using. Synthetic carpets, has been tested in laboratory for a life between eight and ten years, because the wear caused by the stamping and by the atmospheric agents, bring a constant degradation in the years.

TIRES WEEE - Disposal Plant

The consumer electronics is destined for its nature to dump: the generational turnover of the electronic devices become frequenter, the mobiles and computers life shorten, the electronic material to dispose increase in the volume and in the complexity. In particular, this is due to the wireless technologies introduction, that are autonomous energetically and increase the highly polluting volume also of the worn-out batteries. The big diffusion and use in the everyday life of the so-called AEE, electric and elettronic equipment, has forced the necessity to recover the different components, they are composed of, to address them singularly to specific cycle of the recycling, avoiding in this way, a waste of resources, which can be reused to build new technology products. Closely related to the recovering of materials is the issue of the pollution, due to particular polluting and/or toxic components inside these equipments.

TIRES - Recycled Material

As it has known, the industrialization and the development have changed the environmental conditions of the Earth, producing besides wealth, even a wide and often uncontrollable mass of rubbish. The protection of the environment is by now, an issue that one cannot renounce in the civil and industrial society of the third millennium and the law, that aims to guarantee it, is more and more wide and binding. Among them, the used tyre is one of the serious problems to solve because it is a material difficult to treat. In particular, for its elastomeric characteristics it is hard to recover, if the suitable working processes are not adopted. In the European Union the used tyres annual build-up is of about 3.250.000 tons of pieces. In Italy every year about 400.000 tons of tyres are thrown away, 50% of them is intended to a recycling process.

Eco Material Production

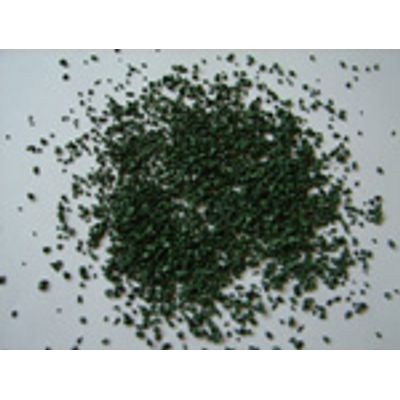

TIRES - Coloring Plant for Rubber Granules

The use of recycled granule and powder has several application sectors. But in the last years, the consume of rubber recycled products has taken the upper hand in the employment for fields of synthetic grass. Since the year 2000, it has been undertaken more and more advanced innovations for the granules production, which make them to have perfect requirement, both granulometric and elastomeric. No less, it has been the innovation in the colouring of the granule called in Italian “nobilitatura” (painting). It consists of a chemical process where the granule is covered from a special coat of colour, making to it take several type of colour.

TIRES - Press Work Plant for Antishock Floor

Although the incentive to the building of used tyres recycling plants represents a very good business chance, the same is the possibility to can satisfy an ecological use of the recycled product. TIRES S.p.A. besides to innovate its recovery lines, studies and acts next to engineering studies for applications in the urban use, thanks to elastomeric property of the recycled rubber granules and powders.