Mining and Metal Smelting

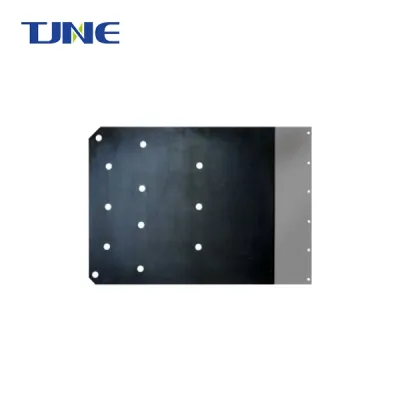

TJNE - Electrodeposited Titanium Electrode for Cobalt Electroplating

The electrodeposited titanium electrode designed specifically for cobalt electroplating enhances efficiency and quality in various industrial applications. This product comprises a titanium substrate, either in bar or plate form, featuring a unique porous titanium coating applied through a proprietary fabrication technique. This structure optimizes the anode's surface area, promoting superior conductivity, activation efficiency, and stability in plating baths. Configured as robust plates or mesh baskets, these electrodes are adaptable to different plating tank designs and maintain their effectiveness through periodic reactivation. Compared to graphite or cobalt-based anodes, titanium variants significantly reduce power consumption and bath contamination while increasing plating rate and uniformity. Ideal for sectors like aerospace, automotive, medical, petrochemical, and electronics, it supports critical processes such as corrosion resistance coatings and decorative and functional alloy applications.

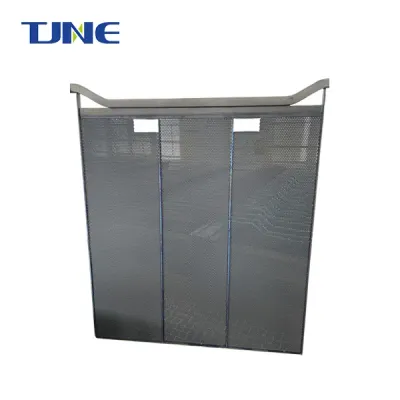

TJNE - Electrodeposited Titanium Electrode for Zinc Electroplating

The electrodeposited titanium electrode for zinc is an advanced electrochemical solution employed in diverse industrial applications, specifically aimed at optimizing zinc electroplating processes. Constructed from superior titanium material, the electrode is characterized by high electrical conductivity and exceptional corrosion resistance, thus ensuring durability and reliable performance in demanding environments. The electrode functions on the principle of electrodeposition, where electrical currents enable zinc ions in the plating solution to be deposited onto the substrate. Designed to enhance plating efficiency and uniformity, the electrode's structure includes a titanium substrate layered with active material, bolstering durability and electrical conductivity. Its customizable sizes and configurations address varied application needs. Extensively utilized in fields like automotive, electronics, aerospace, and general manufacturing, this electrode aids in forming corrosion-resistant zinc coatings on diverse substrates, thereby extending their lifespan and improving operational efficiency and cost-effectiveness in electroplating tasks.