- Home

- Companies

- Torkapparater AB

- Products

Torkapparater AB products

Our Techniques

Torkapparater - Drying System

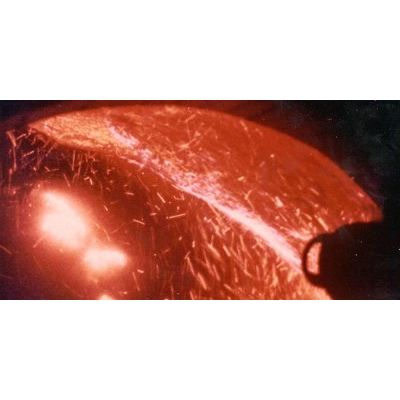

Torkapparater are specialists in the field of indirect heat transmission. Drying with indirect heat transmission implies that the heating medium is never in contact with the material to be processed. The heat transfer is generated through tubes and through the rotary perimeter of the dryer/cooler cylinder.

Torkapparater - Indirect Cooling Processing Technology

Torkapparater is a specialist in the field of indirect cooling processing technology. The technology is developed around a rotary tubular cooler with indirect heat transmission for hot solid materials. Indirect cooling implies that the material to be cooled does not come in contact with the cooling medium. In this way, contamination and dust formation is avoided. The cooling medium is either a gas, typically ambient air, or a fluid, e.g., water that can adsorb the heat. Our technology accurately controls the outgoing materials temperature with minimum variations. Materials suitable for cooling process are for example minerals, lime and gypsum. Other applications are pyrolysed or gasified materials.

Torkapparater - Dust Recovery and Dust Cleaning Systems

In industrial applications there are many dust generation processes that generate air contamination in the form of dust and particles. Dust is dangerous and may harm the lungs and lead to allergic reactions if in contact with the skin. Torkapparater offers different combinations of dust recovery and dust cleaning systems that meet emission levels and are adapted to the respective processes.