- Home

- Companies

- TSC Subsea Limited

- Products

TSC Subsea Limited products

Subsea External Pipeline and Riser Inspection System

Artemis - vCompact

Linear Scanner

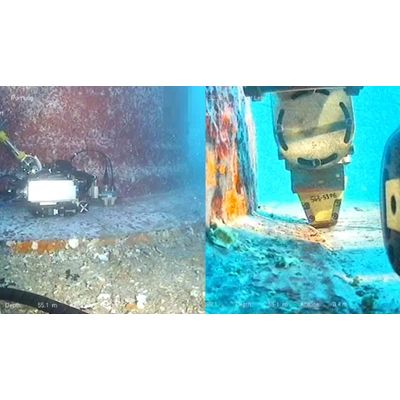

The robust, field-proven TSC Subsea Linear Scanner is a compact, remotely deployed scanning solution specifically designed to fit into restricted-access areas where other inspection scanners simply won’t fit. It is positioned onto the inspection area via an ROV. The scanner’s automated linear scan action ensures smooth and consistent real-time data capture, maximising array probes to cover up to 100% of the inspection area. Once placed in position by the ROV, built-in passive compliance ensures good probe contact during scanning. The LinearScanner™ actively measures the travel distance of the probe, resulting in accurate defect position and sizing.

Subsea Inspection Technology

The TSC Subsea MagCrawler™ represents the latest in remote subsea inspection technology. It was developed specifically to enable the ROV deployment of TSC Subsea’s exclusive ACFM® Array Probes to inspect subsea geometries such as circumferential welds in pipes/tubulars, fillet and full-penetration welds in plates.

NodeScanner System

Certain jacket nodes—fatigue-sensitive nodes—are subject to significant dynamic loading and require regular inspections to detect the initiation of fatigue cracks. The complex nature of the welds rule out inspections via ‘direct scanning,’ even with the best work-class ROVs, and the difficult access and dangerous conditions are often outside the capabilities of divers. TSC Subsea’s field-proven NodeScanner™ system addresses these issues. An ROV places the NodeScanner on the brace, then stands back and monitors the inspection progress. The NodeScanner’s unique teach-and-learn system provides the dexterity and control needed to quickly and accurately scan the area in question.