3 products found

Twister products

Twister - Twister Supersonic Separator

The Twister Supersonic Separator represents a significant innovation in the field of natural gas processing. Employing advanced principles of aerodynamics, thermodynamics, and fluid dynamics, this technology condenses and segregates water and heavy hydrocarbons at supersonic velocities. The design yields profound efficiencies, offering deeper cooling and higher NGL recovery compared to traditional Joule-Thomson (JT) processes. Its near-isentropic expansion method not only minimizes pressure drop but also enhances dewpointing performance. With no moving parts, it ensures long-term reliability and minimal maintenance, as well as superior safety due to reduced hydrocarbon and H2S volumes. Operating succinctly as piping, the compact and robust unit has an impressive capacity to process 30 million standard cubic feet per day (MMSCFD), making it an economic choice by reducing both capital and operating costs. Additionally, its small footprint lends itself to cost-effective offshore installation. By leveraging these efficiencies, Twister's Supersonic Separator offers robust solutions across various applications including Offshore Sweet Gas Dehydration and Offshore Sour Gas Dehydration, leading to higher NGL recovery and ultimately increased profitability.

Twister - Hydrate Separator

The Twister™ Hydrate Separator is a cutting-edge device engineered for the chemical-free separation of hydrates and liquids from natural gas. Utilizing a combination of heating coils and cyclonic separation, this compact and lightweight design ensures high separation efficiency over a broad flow range. It operates within the hydrate region without the use of hydrate inhibiting chemicals, using a patented Low Temperature Separator design. This reliability stems from an improved integration of Low Temperature Extraction (LTX) technology, requiring minimal maintenance even after years of consistent operation. It addresses economic, safety, and sustainability challenges, offering versatility in various applications such as offshore sour gas dehydration and onshore gas dewpointing. The system's safety is enhanced by eliminating the risk of emissions common in chemical systems. Furthermore, the design necessitates less plot space, which is crucial for cost-effective offshore structures. The jacket and liquid heaters ensure the temperature remains above the hydrate formation threshold, preventing blockages in downstream handling systems.

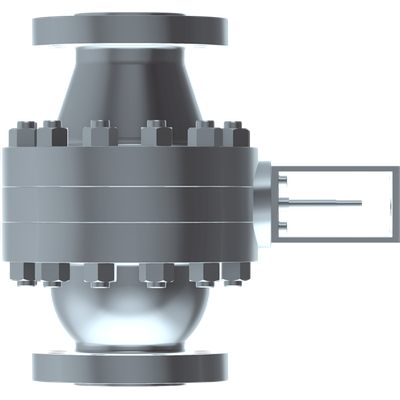

Twister - Pressure Reduction Valve

Twister offers groundbreaking separation solutions for natural gas processing, providing a cost-effective, safe, and sustainable alternative to traditional methods. The Twister technologies encompass dehydration, hydrocarbon dewpointing, and natural gas liquids (NGL) recovery within a single unit, including the innovative Twister™ Supersonic Separator and Twister™ Hydrate Separator. The SwirlValve™ enhances JT operations by improving the efficiency of two-phase flow separation across pressure reduction valves such as choke, JT, and control valves. Technical benefits of the SwirlValve™ include increased flow throughput, enhanced gas handling capacity, and a boost in natural gas production while reducing bottlenecks in overloaded separators. The SwirlValve™ works by utilizing the free pressure drop available in JT operations to create a rotating flow, which increases droplet size and enhances the downstream separation efficiency. Ideal for both offshore and onshore applications, the SwirlValve™ supports various operations from gas dehydration and dewpointing to light oil stripping with gas reinjection. The compact design, reliability, and high performance make Twister’s SwirlValve™ an essential component for improving process profitability and operational flexibility.