- Home

- Companies

- Union S.P.A.

- Products

Union S.P.A. products

Hermetically Sealed Washing Systems Under Vacuum

Hermetically Sealed Washing Systems Under Vacuum

Specifically designed for small components or components with a complex structure such as blind holes. Machines work under vacuum for fast washing cycles and continuous vacuum distillation with automatic final stripping of residues. Union produces an extensive range of machines capable of solving any surface cleaning problem. All machines are designed to use either chlorinated solvents or alternatives such as hydrocarbons or modified alcohols simply by selecting the most suitable solvent type on the PLC. This type of ‘hybrid’ approach leaves the customer with great flexibility of choice at any time throughout the life of the machine, enhancing the investment made. Each model can be customized to allow the use of a wide range of baskets (with fixed or adjustable lids or dividers to provide multiple compartments) and fixtures depending on the components to be treated.

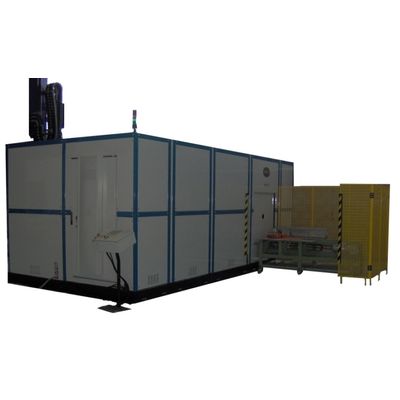

Hermetically Sealed Washing Systems Under Vacuum

Specifically designed for heavy or large loads, components with complex structures, static parts cleaning or processes operating for 24 hours per day. UNION produces an extensive range of machines capable of solving any surface cleaning problem. The machines are capable of processing a single, large basket but this basket can also be used to house numerous, smaller baskets to permit discrete batches of smaller components to be processed simultaneously. MUMV machines operate under vacuum throughout the whole process cycle for faster cycles and continuous vacuum distillation with automatic final stripping of residues. Machines can use with chlorinated solvent, hydrocarbon or modified alcohol simply by selecting the appropriate solvent from the PLC. This type of ‘hybrid’ approach leaves the customer with great flexibility of choice at any time throughout the life of the machine, enhancing the investment made.

Water and Detergent Washing Systems

Hydrokinetic Washing Machine

RH machines are aqueous cleaning systems designed to meet the demand for high specification cleaning of batches of small components, or larger items with complex structures. Components, located inside dedicated stainless steel baskets or fixtures, are cleaned using a high pressure, hydrokinetic washing action or total immersion with ultrasound and vacuum. Depending on the nature and sensitivity of the components, the basket or fixture can be rotated through 360O (either continuous or counter rotation), oscillated, or held static. The RH range comprises of a number of models, based on basket size and throughput requirement. They are completely closed-circuit, with continuous filtration of the washing and rinsing baths and separation of oily residues through closed-circuit oil separators. Drying takes place in a closed or vacuum circuit according to the materials of construction of the components being treated.

High Pressure Basket Rotating Washing Machine

These cabinet machines with rotating basket can be used in the treatment of medium and large components. They are inherently simple systems that are easy to use and do not require special maintenance. Cleaning is undertaken inside a cabinet with an automated, loading door. The machine structure houses up to three, independent tanks holding wash and rinse solutions as defined by the requirements of the cleaning process. Components to be cleaned are placed in the rotating basket and are washed and rinsed using high-pressure sprays delivering filtered solutions from the various holding tanks. Machines are manufactured entirely from stainless steel and are PLC controlled for automated operation. The electrical panel houses a modem to provide remote access for assistance should a problem develop.

Washing Systems for Shoe Soles And Plastic Technical Components

Washing Systems For Shoe Soles And Plastic Technical Components

Building on the many years of experience acquired as the undisputed world leader in the field of closed circuit washing systems, Union is pleased to present the new range of SG Series machines for cleaning shoe soles. The range of machines comprises various models for different throughput requirements and using different types of solvent. Machines utilise either chlorinated solvent or alternatives such as hydrocarbons or modified alcohols depending on the type of soles to be washed, the material of the sole and the treatment required downstream of cleaning.