Universal Seed Care, LLC. (USC) products

Seed Treating Solutions - Hoppers

USC - Vibrating Hoppers

The 80 unit vibrating hopper is an ideal piece of equipment to pre-stage treated seed coming from the seed treater. The built in vibrating unit is ideal for breaking up bridged material to allow constant flow of product into a pro box. The unit comes with a swing out control panel that is accessible to a fork lift driver to control the vibrating unit and the air actuated gate valve to control flow into a bag or pro box.

Seed Treating Solutions - Treater Accessories

USC - Direct Inject Pump

U-Tote Direct Inject allows the operator to hold off blending until it`s time to treat. It creates a perfect, continuous blend and is an easy addition to any operation. A simple process connects the compactly-designed U-Tote directly to the treater. The system was designed to save time, energy and money. U-Tote is the most innovative, user-friendly and affordable direct inject product on the market!

USC Bulk Conveyance

USC - Commercial Bucket Elevators

USC’s Commercial Bucket Elevators (BE) efficiently move commodities at speeds up to 80,000 bushel per hour including grain, meal, seed, feed and pellets. These elevators meet the National Fire Protection Agency’s safety measures equipped with explosion panels and safety cables. Choose from carbon, hot-dipped galvanized or stainless steel with weather-tight options and resistant coatings. Bucket sizes are completely customized based on specific facility requirements, and constructed using outboard pillow block bearings for long-term, reliable use. USC’s bucket elevators are designed to stand the test of time and the elements!

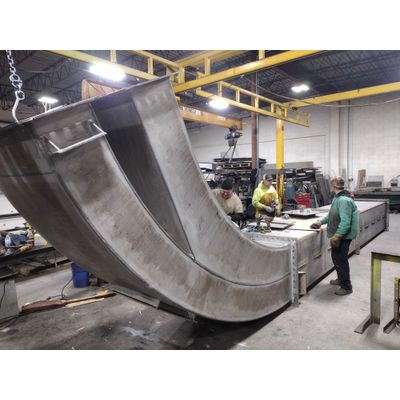

USC - Divided Trough Conveyors

USC’s Divided Trough (DT) conveyors are ideal for moving commodities horizontally to vertically in straight inclines, L-shaped, S-shaped, C-shaped and looped configurations. These unique models truly highlight USC’s innovative approach to providing conveyance solutions throughout the industry, while tackling the challenges that come with harsh conditions with ease, flexibility and configurability. DT conveyors provide reliable movement for multiple materials, are designed and built with a modular mindset to provide convenience during assembly and routine maintenance, and with variable liner sizes, are the perfect solution for continuous operation and high-wear applications.