4 products found

UVFAB Systems, Inc. products

UV Ozone Cleaning Systems

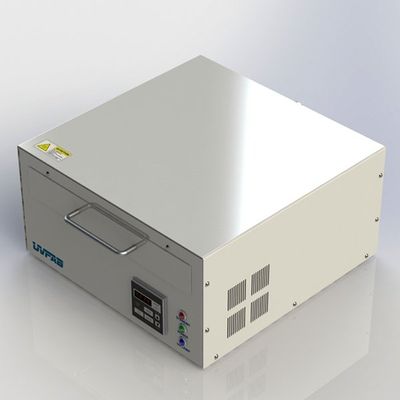

UVFAB - Model HELIOS-500 - UV Ozone Cleaning System

The HELIOS-500 UV Ozone Cleaner is a compact tabletop system designed for effectively removing organic contaminants from substrates using UV light and ozone. It features a high-intensity mercury vapor UV grid lamp producing 254nm ultraviolet radiation, which disrupts organic molecular bonds. The system generates reactive ozone at 185nm, converting atmospheric oxygen to reactive species that help in breaking down these molecular fragments into volatile organics. With a built-in digital process timer, hour counter, and safety interlock switch, it ensures safe and efficient operation. Accommodating substrates up to 5.5 x 5.5 x 1.4 inches, the HELIOS-500 is equipped with a drawer-loaded sample stage, facilitating ease of use in lab environments. It's engineered to provide uniform UV radiation and enhanced ozone production for accelerated cleaning rates, with added convenience of free shipping within the USA and a 2-year warranty.

UVFAB - Model HELIOS-1200 - UV Ozone Cleaner

The HELIOS-1200 UV Ozone Cleaner, manufactured by UVFAB Systems, Inc., is a compact and tabletop cleaning system engineered to achieve molecular-level organic contamination removal, resulting in atomically clean surfaces across diverse substrates. This system employs a high-intensity 12-inch by 12-inch UV grid lamp, which emits 254nm ultraviolet radiation to break molecular bonds on surfaces and 185nm emissions to convert atmospheric oxygen into reactive ozone, targeting the resultant molecular fragments. Capable of handling one 300mm wafer or multiple smaller wafers, this system incorporates a drawer safety interlock, a digital timer for process management, and an hour counter for monitoring lamp lifespan. The HELIOS-1200 operates at atmospheric pressure, obviating the need for complex vacuum systems, and is ideal for applications such as substrate cleaning, photoresist descumming, surface modification, and UV curing, without risking damage to sensitive electronic components.UV Curing

UVFAB - UV-LED Spot Curing System for Controlled UV Curing Applications

The UVFAB UV-LED spot curing system is a compact, high-intensity solution designed for applications requiring precise UV curing. Featuring LED technology, it is equipped with a controller and enables independent operation of up to four UV-LED heads, supporting wavelengths of 365, 385, 395, and 405 nm. This system includes 8mm focusing lenses for tailored coverage and control, allowing users to set specific exposure times and intensity levels for each LED head. Utilizing UV LEDs, this system provides a narrow spectral output, reducing substrate temperature and making it suitable for curing heat-sensitive materials. The UVFB LED curing system stands out for its energy efficiency with benefits such as no warm-up time, decreased energy usage, and consistent wavelength delivery, resulting in improved process management. The system features a user-friendly interface for easy setup and activation via foot pedal or controls, offering versatility and efficiency for advanced UV curing tasks.

UVFAB - Model UVC-408 - Compact Tabletop UV Curing System Model UVC-408

The UV Curing System Model UVC-408 by UVFAB Systems, Inc. is tailored for processes involving 200mm (8-inch) wafers. This tabletop system integrates a high-pressure mercury UV lamp, providing a practical solution for compact workspaces. It is crafted to meet the unique demands of the semiconductor industry in areas such as wafer processing and curing applications. The UVC-408's design enhances efficiency while maintaining a compact form factor, making it a first in the industry for its size and functionality. With its targeted application in UV curing, the system's capabilities are optimized for precision and reliability, adhering to stringent technological standards. It is particularly relevant for professionals seeking advanced compact UV solutions for semiconductor wafer technologies.