- Pulp - Complete Pulp Mill

- Board and Paper - Recycled Fiber -OCC Lines- Bale Handling and Pulping

- Board and Paper - Recycled Fiber -OCC Lines- Cleaning -Low Consistency Hydrocyclones

- Board and Paper - Recycled Fiber -OCC Lines- Screening

- Board and Paper - Recycled Fiber -OCC Lines- Thickening and Clarification

- Board and Paper - Stock preparation - Bale handling and Pulping - Bale Handling

Valmet products

Pulp - Complete Pulp Mill

Valmet - Chemical Pulping Mill

At Valmet, we have unbeatable experience and technical know-how of the entire pulp mill with all its islands and processes. We offer tailored technology solutions for softwood, hardwood and kraft pulp production. Advanced technology, trustworthy service, and flexible automation - these are the three pillars that make Valmet`s offering unique. With enhanced production optimization, we help you move your pulp business forward.

Board and Paper - Recycled Fiber -OCC Lines- Bale Handling and Pulping

Valmet - Drum Pulping Mill

Valmet Drum pulper’s high consistency treatment enables efficient fiberizing and ink detachment even from very contaminated furnish. The gentle slushing action of a drum pulper does not break up impurities, making them easier to remove in the subsequent process stages. Continuous operation stabilizes and improves the efficiency of the entire process, ensuring consistent pulp quality.

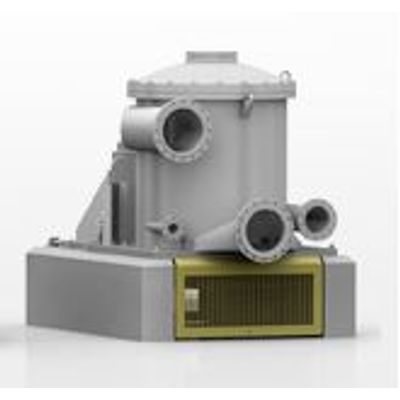

Valmet - Vertical Pulper Station

Valmet Vertical pulper station efficiently achieves critical OCC process targets. The secondary pulping system gives maximal outthrows removal with energy efficiency and high yield in an extremely compact package. Featuring enhanced removal of harmful impurities such as wire, steel and plastic, the Valmet Vertical pulper can significantly maximize pulp quality and production line runnability.

Valmet - Recovered Paper Bale Tester

Recovered paper is a valuable raw material, not waste. With Valmet Bale Tester you get objective view on the raw material quality. It measures the moisture and other features of the raw material in real time.

Board and Paper - Recycled Fiber -OCC Lines- Cleaning -Low Consistency Hydrocyclones

Valmet Twister - Hydrocyclone

An optimal solution for high-consistency, high-demand hydrocyclone applications. Operating at up to 2% consistency, this two-stage hydrocyclone features three forward hydrocyclones in one, single unit. Valmet Twister Hydrocyclone features Mid-cone Dilution Technology and delivers energy savings with lower applied energy and lower reject rates than conventional Hydrocyclones.

Board and Paper - Recycled Fiber -OCC Lines- Screening

Valmet - Coarse Screens

Valmet’s coarse screens are designed for all coarse screening applications in recycled ï¬ber processing and stock preparation. Coarse screens effectively remove heavy, light and coarse particles and contaminants from pulp, protecting subsequent process equipment from potential damage.

Board and Paper - Recycled Fiber -OCC Lines- Thickening and Clarification

Valmet - Disc Filter

Disc filters have many applications in pulp and paper mills for stock thickening. They are commonly used in the paper mill as save-alls for the recovery of fiber and filler, and for clarification of whitewater. Modern disc filter save-alls now produce clear and super-clear filtrates for stock dilution and machine showers that minimize freshwater use.

Valmet - Screw Press

Screw pressing applications cover various thickening process needs from sludge dewatering and reject handling to stock thickening.

Board and Paper - Stock preparation - Bale handling and Pulping - Bale Handling

OptiSlush - Bale Pulping Unit

Valmet’s OptiSlush bale pulping solutions are suitable for either batch or continuous pulping applications utilizing reliable repulping technology to achieve optimum slushing with maximum energy efficiency. Valmet’s bale pulping solutions, including vertical and horizontal pulpers, offer cost-efficient repulping of baled market pulps. A vertical pulper is the best choice when targeting homogeneous slushing results with low energy consumption, while a horizontal pulper, with its low height requirement, is ideal for rebuilds where limited space is available.