- Home

- Companies

- VAPOR-NOVA

- Products

VAPOR-NOVA products

VAPOR-NOVA - Professional Pressure Washers

Vertical heating boiler equipped with an electric motor independent from that of the water pump in order to allow cold operation without involving the diesel pump. Air conveyance cavity that allows both the cooling of the combustion chamber and the preheating of the combustion air Coil in seamless steel tube. Three ceramic piston pump flanged directly to the electric motor. Automatic pressure regulation valve.

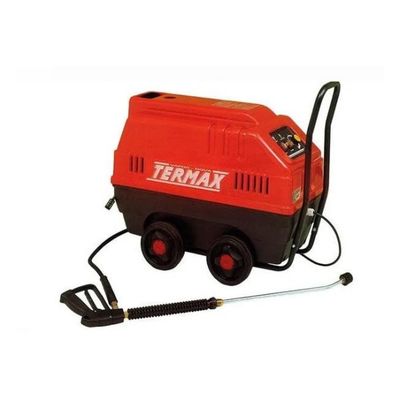

VAPOR-NOVA - Professional Pressure Washers

Three piston pump. On Termax 140 pump at 1400 rpm. Pump motor with automatic reset motor protection device. Pressure regulation valve with automatic operation. High performance boiler with coil in seamless steel tube ø 17 mm having a development of mt. 21 (allows to reach the temperature of 90 ° with a low consumption of diesel). Burner motor independent from that of the water pump to allow cold operation without the risk of damaging the diesel pump in the absence of fuel.

VAPOR-NOVA - Blades for Shredders

Blades and grinders for shredders with both standard and on request profiles. Complete set of spacers and cleaning sectors for shredder. Sharpening and grinding used and worn blades. Blades and knives for mills and scrap shears. Repair and overhaul shredders - revised used shredders.

VAPOR-NOVA - Professional Pressure Washers

Three ceramic piston pump. High efficiency boiler with seamless steel tube coil ø l7 mm having a development of 28 meters which allows to reach high temperatures with low consumption of diesel. Burner motor independent from that of the water pump to allow cold operation without the risk of damaging the diesel pump in the absence of fuel.

VAPOR-NOVA - Hydrocleaning System

The models of F2 & F3 cold water high pressure cleaners have three ceramic piston pumps flanged directly to the electric motor at 1400 rpm. Automatic pressure regulation valve. Predisposition for TOTAL STOP device. On F2 detergent tank with adjustable device on the lance for drawing additives in low pressure. STANDARD EQUIPMENT: athermic lance with gun control, high pressure hose mt. 10 (on F3 tube ap mt. 15). OPTIONAL ACCESSORIES: sandblasters, rotating nozzles, rotating hydrobrush, probes and cleaning nozzles.

Hydrocleaning System

Pump with three pistons. Pump motor with automatic motor protector. Detergent tank. Adjustable device on lance for suction lift of low pressure additives.