Bin Activators & Bin Dischargers:

Vibra Screw - Bin Activators and Heavy Duty Bin Dischargers for Dry Bulk Material Handling

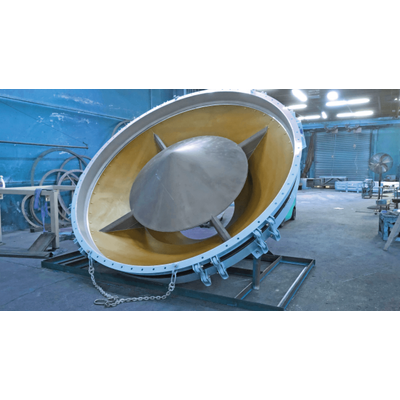

Vibra Screw offers specialized equipment for the movement and discharge of dry bulk materials from silos and bins. Their legacy began with the invention of the Bin Activator over six decades ago. These activators are crucial in preventing common flow issues like bridging and ratholing, ensuring consistent mass flow. The company provides three main designs: the Dished Head, Model HDBD with a compound slope body, and the rolled cone Bin Discharger. The Heavy Duty Bin Dischargers, designed for larger silos, combine an upper shallow section with a steep lower cone, eliminating packing and bridging without secondary baffles. Noteworthy features include a robust forged steel suspension system with elastomer isolators to minimize vibration transfer, patented beaded sleeves that resist leakage and withstand pressure, and a choice of oil or grease-lubricated vibrators designed for long service life. These products cater to a wide range of industries handling some of the most challenging materials.

Vibra Screw - Bin Dischargers for Dry Solids Processing

Vibra Screw, a company renowned for its contributions to dry solids processing, offers a line of reliable and cost-effective Bin Dischargers. With over half a century of experience, these devices are crafted with durability in mind, ensuring a long-lasting performance that meets industry standards. Their compact, leak-proof design includes a heavy-duty suspension system and long-life vibrator, making installation straightforward and maintenance minimal. Vibra Screw's Bin Dischargers are available in both carbon and stainless steel and can be delivered promptly. Particularly notable is the proprietary ASME dished head design utilized in their Bin Activators, which enhance strength and flow patterns in larger models. For smaller applications, their Bin Dischargers, with a rolled single-slope cone design, effectively prevent material packing at the outlet. This adaptability across sizes and materials makes Vibra Screw a trusted provider in the sector.