- Home

- Companies

- VIEW Micro Metrology

- Applications

VIEW Micro Metrology applications

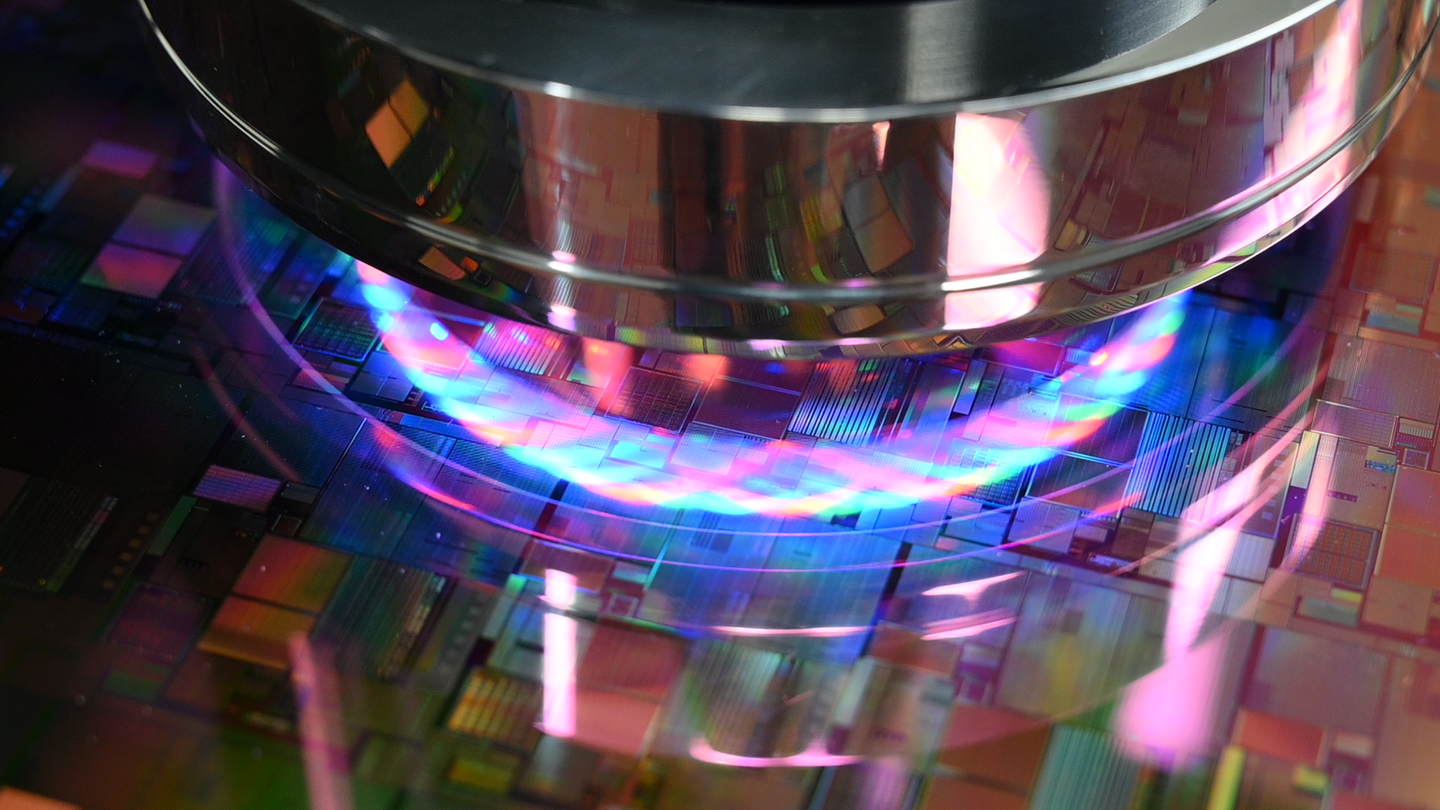

Component placement verification in electronic assemblies presents metrology challenges that are almost as wide and varied as the range of electronic designs and the types of components used. Key process control parameters that must be measured include component positioning and rotation (X, Y, and theta) relative to pads, as well as checking for missing and/or damaged components.

As the leader in microelectronics metrology solutions for more than two decades, VIEW brings together the applications awareness and metrology expertise needed to address even the most demanding interconnection challenges with proven platforms. Some of the specific microelectronics interconnection applications that are addressed by VIEW solutions are listed below.

Metrology solutions for fiber optic interconnect components (“ferrules”) require high accuracy and throughput. One of the critical dimensions is the concentricity of the outer housing to the fiber optic center. This ensures proper interface to support high-speed communications infrastructures.

The effective inspection of PCB connectors requires metrology solutions that can accurately measure a wide variety of connector dimensions while providing the fast cycle times and throughput required for high-volume near in-line production-oriented processes. Efficient and highly repeatable measurement capabilities are needed to quickly acquire data on lead (male) and slot (female) connector positions along with size, pitch, and coplanarity measurements.

Flex circuit technologies pose a wide range of metrology challenges with a large number of different circuit geometries, pitch dimensions, and surface reflectivity factors. To meet these challenges, metrology systems for flex circuit inspection must incorporate advanced functionality such as versatile lighting, large-size stages, high-resolution positioning, and very accurate laser probe capabilities.

Inspection and process control for maintaining quality assurance over PCB artwork and bare-boards represent especially challenging requirements for metrology systems.

Mis-registration of solder paste relative to printed circuit board pads is one of the leading causes of scrap and rework in surface mount technology (SMT) board assembly. In addition, height and volume measurements are crucial to new process development and to the optimization of existing processes.

Production inspection of hard drive Head Gimbal Assemblies (HGAs) requires the accurate measurement of a number of critical factors to meet tight tolerances. These include pitch and roll angles, slider positioning, and slider orientation/alignment issues.