Vikotech Makina products

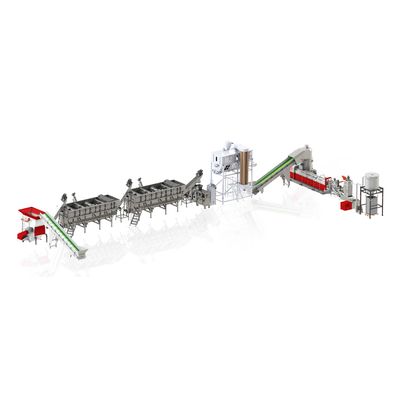

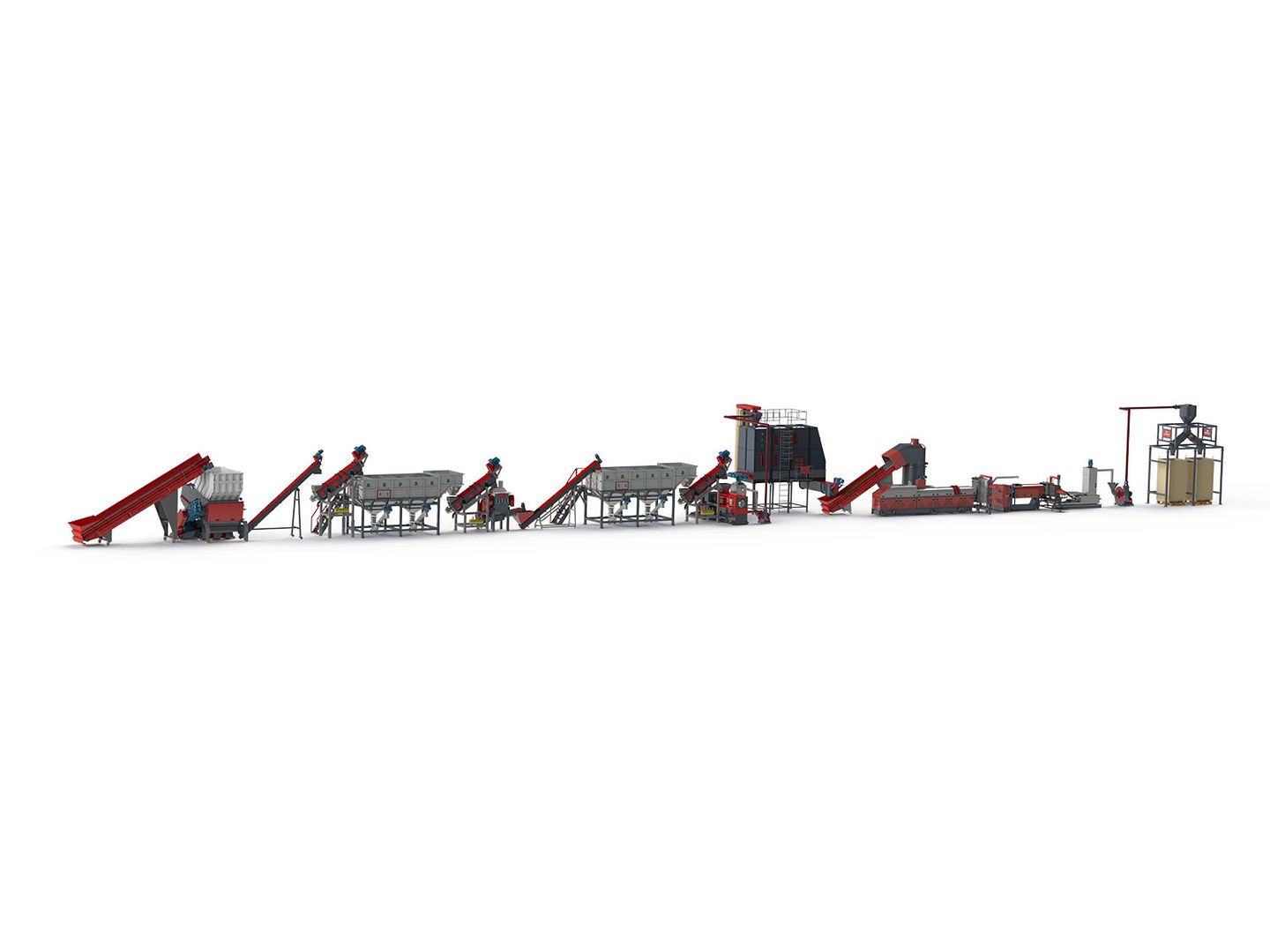

Plastic Recycling Line

VikoTech - Compactor Plastic Recycling Line

These are the lines used for recycling rigid or film (soft) waste polyethylene (LLDPE, LDPE, HDPE) and polypropylene (PP). At the beginning of the line, the plastic waste is shredded using a shredder or a crusher. The shredded plastics are transported to the washing plant by the appropriate transport unit. The plastics are washed by a friction system under high speed in centrifuges and separated from heavy plastics and other heavy contaminations in plastic separating tanks. These plastics are then recycled into reusable granules form using an automatic compact extruder or a combination of agromel and extruder. The equipment is designed according to the degree of contamination of the material and the capacity.

Rigid & Film Recycling Line

These are the lines used for recycling rigid or film (soft) waste polyethylene (LLDPE, LDPE, HDPE) and polypropylene (PP). At the beginning of the line, the plastic waste is shredded using a shredder or a crusher. The shredded plastics are transported to the washing plant by the appropriate transport unit. The plastics are washed by a friction system under high speed in centrifuges and separated from heavy plastics and other heavy contaminations in plastic separating tanks. These plastics are then recycled into reusable granules form using an automatic compact extruder or a combination of agromel and extruder. The equipment is designed according to the degree of contamination of the material and the capacity.

Granule Extrusion Systems

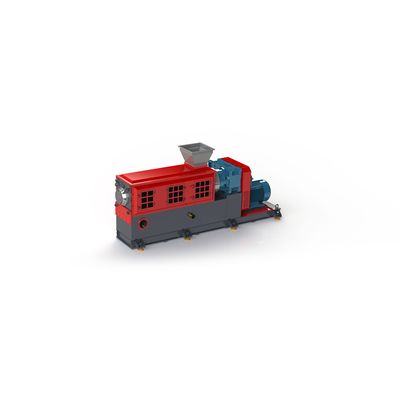

Compactor Extruder

Our VK-CP extruder was made with the latest technology in recycling systems. It is the easiest to operate, offers the highest benefits and the lowest operating cost ratio among plastic granule extrusion systems. VK-CP The extruders require minimum manpower thanks to its automatic operating system. VK- CP extruders process plastic in all forms “burr, bran, foam” of: LDPE, LLDPE, HDPE, PP, PS, ABS material types. Even plastics with high moisture content up to 7% can be pelletized without problems.

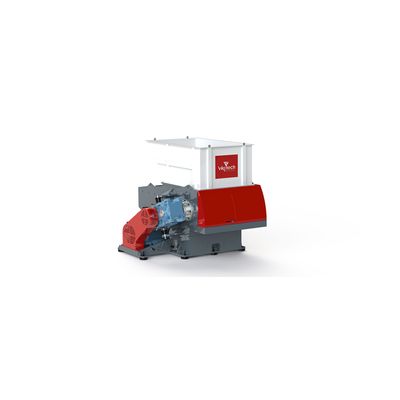

Shredding Systems - Single Rotor Shredder

Model Angled - Single Rotor Shredder

Single Rotor Shredders are used for size reduction of all types and forms of plastic scrap, cardboard, tex- tile, carpet, paper waste without getting affected by thickness and density of material. Rotor, blade, feeder and screen model is chosen according to the type and form of scrap to quarantee high capacity. Straight, inclined or swing type feeders are used for different forms of scrap and feeders can be powered by hydraulic or pneumatic power. Feeders are controlled by PLC system.

Model Straight - Single Rotor Shredder

Single Rotor Shredders are used for size reduction of all types and forms of plastic scrap, cardboard, tex- tile, carpet, paper waste without getting affected by thickness and density of material. Rotor, blade, feeder and screen model is chosen according to the type and form of scrap to quarantee high capacity. Straight, inclined or swing type feeders are used for different forms of scrap and feeders can be powered by hydraulic or pneumatic power. Feeders are controlled by PLC system.

Plastic Washing & Drying System

Plastic Washing, Sink & Float Tank

They are used for separating the floating plastics from contaminants like heavy plastics, mud and metals, Contaminants can be easily discharged by the under-tank discharge valve. Sink & float tanks are designed with maximum cleaning, minimum material loss method. Sink & float tanks can be made of AISI 304 stainless steel or DKP sheet, and length 3000mm-6000mm according to customer’s demand.

Plastic Film Dryer (Compactor)

Horizontal Drying Machine of film plastics, mechanical it is used for drying by squeezing method. During the drying process, the ceramic used the resistances reduce the humidity of the product to a minimum. By lowering it. No need for an agromel machine in the next process. Directly to the Granule extruder machine, without by doing this, the product finds the opportunity to work. In this way saving energy and manpower. Moisture rate of plastics as a result of Horizontal Drying process it is reduced to 0.5 – 2%. It is applied to the outlet section of the horizontal dryer. Special mirror and exit system, product quality and product form, without damage, in one measure and dehydrated way, it provides its output. Extruder type screw and barrel in horizontal dryer is used The screw is subjected to heat treatment is hardened.

Film Squazer Machine

Plastic Film Dewatering Machine is one of the most important machines in Plastic Recycling line. All the crashed and washed contaminated Plastic FILM materials, dewatered by this machine. Material dewatered mechanically and it will not require an operator. Special designed heavy-duty screw and barrel will reduce the humidity level down to 4 – 8 %, and this will reduce the electricity consumption for next drying phase.