Viscon Plant Technology products

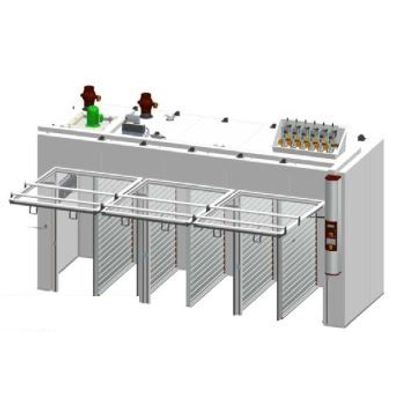

Viscon - Model ViCabin - Climate Chamber

The ViCabin is a climate chamber in which humidity, temperature, and C02 values can be set to achieve accurate and uniform growing conditions. The climate chambers create the ideal environment for your indoor multilayer production.

Viscon - Model ViCabin 1 - Trolley

Power in: 400V/3Phase/60Hz - 2,52kW. Power trolleys: 90-305V/1 phase +N/50/60Hz - 600W. 08mm push-in: Humidification RO water - 7L/h @ 1,5 Bar. 022mm push-in: Cooling water in/out - 1.6kW chilled water cooling. 0160mm: Inlet clean air - 600m3/h

0160mm: Outlet clean air- 600m3/h.

Conveyors

Our conveyors are designed for the supply and discharge to and from machinery in your automation project, Viscon supplies conveyors that can be adapted to almost any product or product carrier. The standard conveyors that we offer are in a variety of widths from 200 up to 3000 mm. If necessary, we will look at the integration of your conveyor systems to develop an automated solution incorporating “loose” products, racking and trolleys etc. We offer different conveyors such as belt, roller (driven and non-driven) and chain conveyors, for different products, pallets and crates. Available in different materials as well as curved and spiral conveyors.

Industrial Washing Machines

Unifortes specializes in an industrial cleaning technology for Agro and Food production companies. In the areas of Agro and Food, hygiene is extremely important and an excellent result is an absolute requirement. We offer turn-key solutions for handling the entire cleaning and drying process. Our product range varies from stand-alone crate washers to the turn-key delivery of a fully automated washing and handling plant.

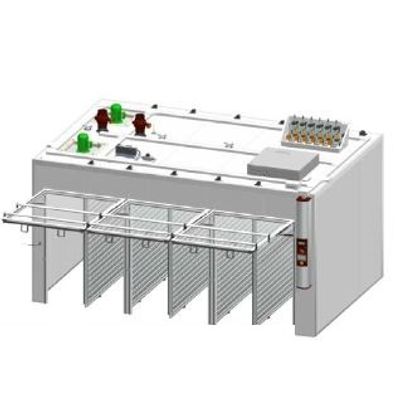

Viscon - Model ViCabin 6 - Trolley

Power in 400V/3Phase/60Hz – 2,87kW. Power trolleys 90-305V/1phase +N/50/60Hz – 600W. Ø8mm push-in Humidification RO water – 7L/h @ 1,5 Bar. Ø22mm push-in Cooling water in/out – 4,5kW chilled water cooling. Ø160mm Inlet clean air – 600m3/h

Ø160mm Outlet clean air – 600m3/h.

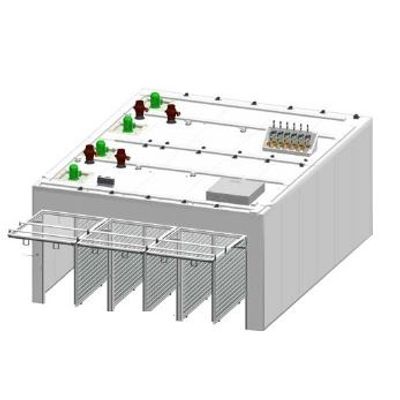

Viscon - Model ViCabin 12 - Trolley

Power in 400V/3Phase/60Hz – 10kW. Power trolleys 90-305V/1phase +N/50/60Hz – 600W. Ø8mm push-in Humidification RO water – 14L/h 1,5 Bar. Ø22mm push-in Cooling water in/out – 17.6kW chilled water cooling. Ø160mm Inlet clean air – 1.200m3/h

Ø160mm Outlet clean air – 1.200m3/h.

Viscon - Model ViCabin 24 - Trolley

Power in 400V/3Phase/60Hz – 10kW. Power trolleys 90-305V/1phase +N/50/60Hz – 600W. Ø8mm push-in Humidification RO water – 14L/h 1,5 Bar. Ø22mm push-in Cooling water in/out – 17.6kW chilled water cooling. Ø160mm Inlet clean air – 1.200m3/h

Ø160mm Outlet clean air – 1.200m3/h.

Sorting Systems

Viscon’s sorting systems can sort various products by code, weight, shape, size, colour and quality. The sorting can take place by means of camera technology, weighing systems or by help from transponders and barcode labels. As well as the extensive possibilities of these systems, Viscon can also supply bespoke sorting machinery for specific products. Camera systems can also be used for other purposes such as counting, assembly control, product identification and location of randomly positioned products.

Transport and Handling Systems

With 45 years of experience in material handling equipment, Viscon is able to provide its customers with the most efficient solutions and high quality equipment. The experience of Viscon in material handling can cover practically every part of the production process connected with the handling of “product carriers”. Together with the integrated software, Viscon successfully completed a large number of complex projects all over the world in different sectors.

Weighing Systems

Viscon not only supplies a variety of weighing systems from selected manufacturers, like desk top scales, floor scales and belt weigh systems, but also check weighing systems (with or without metal detectors), which can be part of a production line as well as an “end of line” weigh unit for packed and unpacked products. Additionally, Viscon supplies Linear weighing units and units for special applications.