- Home

- Companies

- Vodatech, s.r.o.

- Products

Vodatech, s.r.o. products

Flotation

Vodatech - Chemical Units Used for the Preparation and Dosing of Flocculant, Respectively Coagulant

The chemical units are used for the preparation and dosing of flocculant, respectively coagulant. These chemical additives are used to intensify the process of flotation, i.e. causing precipitation of emulsified pollution, formation of flakes, which are easily separated by the flotation.

Vodatech - Flotators Device for Physical Process

Flotators or the flotation units of the VODATECH company operate on the principle of flotation. Flotation is a physical process in which, unlike the sedimentation, there is a lifting of solid, in water suspended particles by fine air bubbles to the surface. On the surface gradually forms a compact layer of compacted sludge that is wiped.

Filtration - Drum Screen

Vodatech - Wastewater Drum Screen

As the rotary screen is used for continuous separation of solid pollution in waste water but with reversed principle. Polluated water is transported by a pump or flows by its own gravitation into the rotatingdrum screen. The water flows through the slots of the screen and falls into the outlet tank, then through the pipe out of the drum screen (into the sump,sewerage). Impurities exceeding the opening size of the slot remain on the internal surface of the screen and by the rotation of the screen they are convoyed by the screw to the open side of the screen .The screenings slide down and fall into a container or onto a conveyor.

Vodatech - Wastewater Drum Screen

It has the same construction as the drum screen S, only the rotating drum is made from perfored sheets with round holes 1,2 - 3mm accordingly the needed filtation. This type is especially used for the separation of fiberous pollution, usually it is installed as protection of Membrane process for removal of hairs from the waste water.

Filtration - Rotary Screens

Vodatech - Rotary Screens

Rotary screen RS is used for continuous separation of solid pollution in waste water. The main operational part of rotary screen is a slot tube which is a welded structure with support profiles which are rods in the axial direction of the tube and surface profiles spirally wound around the support profiles. Water is conveyed by a pump or flows with gravity on the slot tube and passes through slots. The solid pollution that exceeds the dimension of the slot, remains on the exterior of the rotating slot tube and it is scrapped and falls down in a container. Treated water, free of solid pollution, flows out from the lower part of the rotary screen.

Vodatech - Rotary Screens

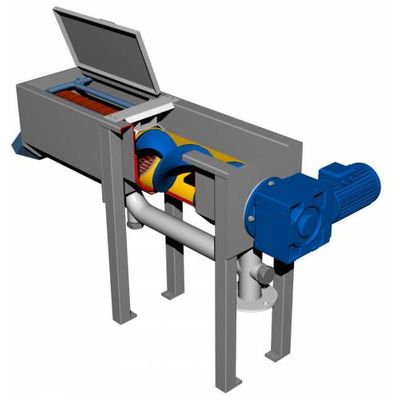

Rotary screen RC is based on the RS serie but in addition has the integrated compactor. The screenings slide down the skimmer and fall through the feeder into the rotating screw. The screenings move through the screw and are pressed into the slotted screen. A thrust plate at the end of the screen exerts counterpressure needed to compact the screenings and dewater them as much as possible. While the thrust plate resistance is broken, the dewatered screenings fall into a container. Treated water, free of solid pollution, flows out from the lower part of the rotary screen.The water from screening goes directly to the outlet tank of the screen.

Filtration

Vodatech - Worm Screens Used for Municipal and Industrial Wastewater Treatment Plants

Worm screens are used for municipal and industrial wastewater treatment plants, where it is used to capture and discharge of solid impurities from the feed wastewater. They are installed directly into the concrete channel, or mounted in a custom metal sump. Sealing frame screens for concrete walls channel, or the metal walls of the pit are using plastic or rubber elements. The water is filtered through a sieve, which is made of stainless steel with different sized round holes. Impurities collected on a sieve are discharged by the screw.

Vodatech - Screw Conveyors and Screw Presses

Screw conveyors SD series are devices used primarily to transport the screenings from rotary screens or separators in wastewater treatment plants. It is also possible (after consultation with the manufacturer), to use the screw conveyor for transport of various materials. It is used mainly in waste water treatment plants in food industry, municipal watewater screenings, paper and pulp industry, brewery waste etc. The screenings fall through the feeder into the rotating screw. The screw rotating the rough is assured by the electrical gear box. The screenings move through the screw from the feeder to the outlet from the screw. The screw conveyor can be inclined up to the angle of 30°.

Sludge Dewatering System

Vodatech - Sludge Dewatering Screw Presses

The sludge dewatering screw presses are used for a continuous dewatering of urban and industrial sludge. Depending on the nature of the input sludge from the municipal wastewater treatment plants, the output concentration of 18-24% solids can be reached. Sludge falls out of the auger continuously into the container or on the screw conveyor. A slowly rotating auger (within 2 rev. / min.) and the solid screen, due to the small number of rotating parts, provides low maintenance costs. The main advantages are reliable, continuous, fully automatic operation with noise levels to < 60 db, very low power consumption (up to 3kW complete unit with peripherals) and easy operation.

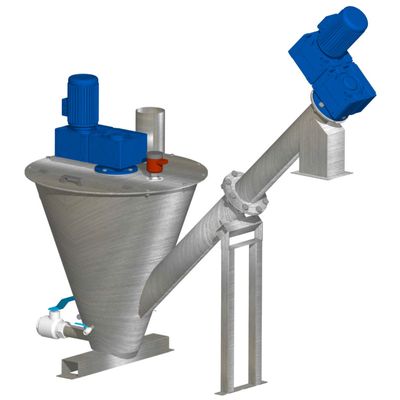

Vodatech - Sand Washing Machine

The sand washing machine ensures the removal of residual organics. Sediment from a sand trap, which typically includes a mixture of inorganic substances, organic substances, and sand, is pumped into the sand separator where the separation of coarser sand occurs. The sand washing machine is preceded by the sand separator and ensures the removal of residual organics.