- Home

- Companies

- Wagstaff Inc

- Products

Wagstaff Inc products

Wagstaff - Billet Casting Systems

Wagstaff AirSlip - Billet Casting System

The Wagstaff AirSlip Air Casting Technology produces the highest quality billets, known for their smooth surface finish, small shell zone, and uniform-grain structure — the world standard for billet quality.

Wagstaff NuMax - Billet Casting System

The Wagstaff NuMax Billet Mold technology is second in product quality only to the AirSlip® Air Casting Technology. NuMax molds have been designed, tested, and proven to meet or exceed all but the most restrictive end-product requirements. The key advantage to NuMax technology is that it offers significantly improved productivity to the billet producer while reducing maintenance time and costs.

Wagstaff - Model ARC - Large Diameter Billet Casting System

To meet growing demand for aerospace alloy material, Wagstaff developed the ARC mold technology to address the challenges inherent to large diameter, aerospace alloy billet production. Utilizing a combination of refined casting recipes, an advanced mold design, and features developed distinctly for aerospace and common alloy aluminum casting in large diameters, ARC technology provides billet casters the ability to produce aerospace (strong) and common alloy billet in sizes greater than 530 mm.

Wagstaff - Rolling Ingot Casting Systems

Wagstaff Epsilon - Rolling Aerospace Ingot Casting System

The Wagstaff Epsilon Ingot Casting System for Aerospace Alloys is an advanced, specialized technology designed specifically to cast strong alloys for aerospace, military, and commercial applications. The system consists of a mold table, molds, starting head base, and starting heads engineered to produce aerospace alloys of the highest quality and in the most efficient manner.

Wagstaff Epsilon - Rolling Ingot Casting System

The Epsilon mold is a robust, easy-to-use upgrade from Wagstaff’s conventional Water Hole Mold ingot technology and is designed to allow operation at metal levels that result in improved cast surface quality. Epsilon`s performance has been consistent, and its usage has increased steadily around the globe as ingot casters discover its effectiveness and practicality.

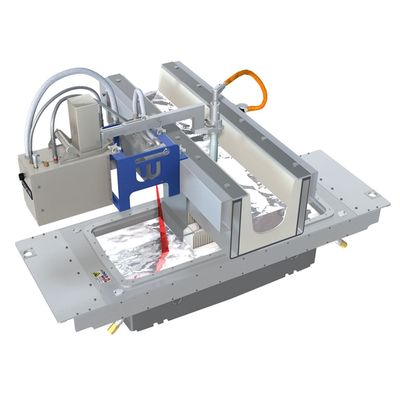

Wagstaff - Model LHC - Low Head Composite Rolling Ingot Casting System

The Wagstaff LHC Low Head Composite Rolling Ingot Casting Technology was developed to improve ingot quality and recoveries. The high quality ingots produced with LHC molds yield significant savings in scalping and edge trimming operations. LHC also allows increased casting speeds and significant reductions in lubricant consumption compared to conventional DC casting.

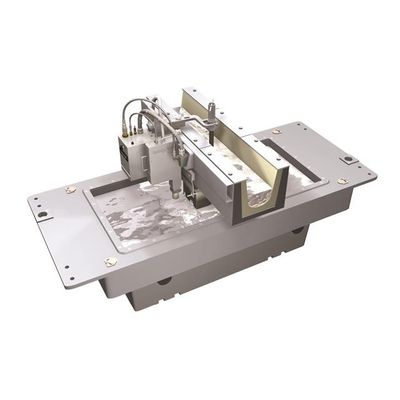

Wagstaff - Model VariMold - Low Head Composite Rolling Ingot Casting System

Wagstaff LHC Low Head Composite Rolling Ingot Casting Technology molds are available as either a fixed dimension mold or a variable dimension mold, known as VariMold. This allows aluminum producers to cast high quality ingot in a variety of widths using a single mold. Wagstaff LHC technology improves ingot quality and recoveries, yielding significant savings in scalping and edge trimming operations. Additionally, tests have shown head and butt crop reductions of up to 50% using LHC vs. EMC because of improved butt geometry.

Wagstaff - Ingot Mold Metal Level Control Technologies

Wagstaff - Model 2345 - Metal Control Actuator with LMI Gocator

The Wagstaff mold metal level controller with LMI Gocator 2345 Castline laser sensor provides precise measuring device with a small footprint for measuring the level of molten metal in the ingot mold bore. The compact, versatile mounting capabilities allow for flexibility in mold sizes and advanced molten metal level measurement not achieved in other applications.

Wagstaff - Metal Flow Control Valve Actuator with Inductive Sensor

The Wagstaff mold metal level controller with inductive sensor provides a robust, reliable way to measure molten metal in the mold bore. This sensor combines the proven technology of the Wagstaff inductive MMLC with pin positioner in a smaller, lighter, more functional, and easier to use sensor package than Wagstaff`s previous inductive sensor/actuator bundles. The versatile separated sensor and actuator arrangement improves the ease of maintenance and setup, enables level sensing into smaller mold sizes, and provides an extended measuring range of 304.8 mm.

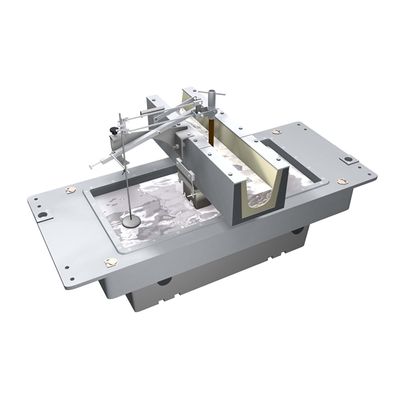

Wagstaff - Steady-Eddy Mold Metal Level Control Device

The Wagstaff Steady-Eddy mold metal level control device is ideal for less demanding ingot casting applications. The Steady-Eddy incorporates a four-bar mechanism that produces near linear movement of the float in the mold. This type of mechanism reduces the error created when the float does not move vertically in the mold cavity. The pivot points have stainless steel shoulder bolts and bearings with a very low coefficient of friction. After a steady state setting is achieved, the pin preset position can be easily set, and allows for hands-off control thereafter.