Walker Process Equipment products

Headworks - Grit Removal

Walker - Rolling Grit Equipment

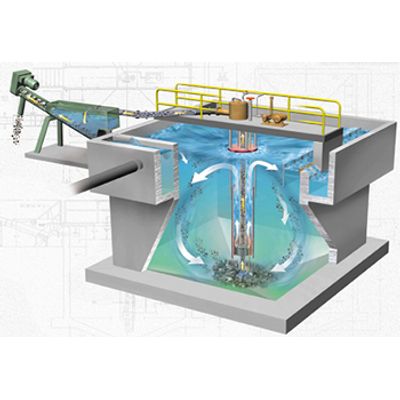

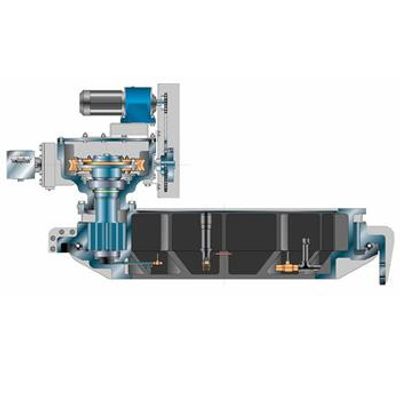

Rolling Grit Equipment from Walker Process provides a total system for grit removal and dewatering. Efficient grit removal is a necessity to provide protection from the abrasive effects of grit on plant equipment and to prevent high grit loads on digesters. In the grit basin, a centrally located eductor tube induces a rolling action that maintains organics in suspension while causing settled grit to be carried to a center hopper where an airlift pump transfers the grit to an inclined screw GritWasher external of the basin. Important features of the Rolling Grit design are that preaeration is provided and the absence of moving parts in the grit basin reduces costly maintenance associated with screws or chain and flight mechanisms.

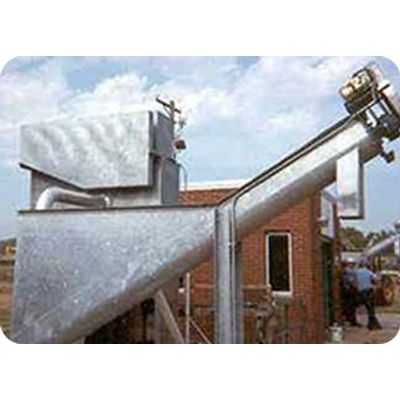

Walker - Grit Washers

Application: Dewatering and cleaning of grit after removal from plant flow.

Biological Treatment - Fixed Film

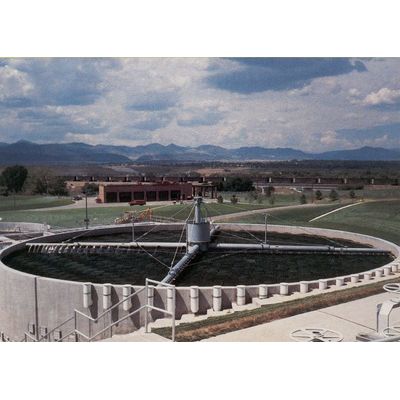

Walker - Rotary Distributors

Mast Type: Type M RotoSeal rotary distributors distribute wastewater over trickling filter rock or media to ensure uniform filter loading. Inlet water is introduced at the mast or center column and flows out to either 2 or 4 distributor arms through a sealed manifold. The arms are fitted with field-adjustable orifices and spreaders and the mechanism rotation is driven by the hydraulic force of the flow. The Type M is applicable to filter diameters up to 175 feet and nominal flow rates up to 5,000 GPM.

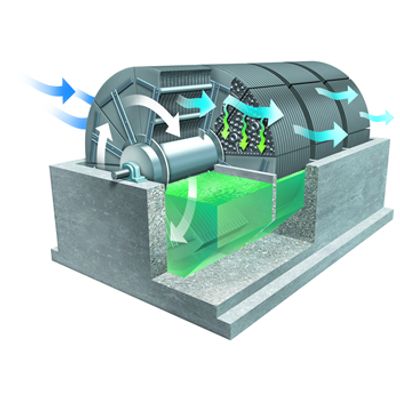

EnviroDisc - Rotating Biological Contactors (RBC)

EnviroDisc Rotating Biological Contactors (RBC) provide highly efficient fixed film BOD and ammonia removal with low energy usage and maintenance requirements. In the RBC process, wastewater flows through shallow tanks containing the partially submerged, rotating shafts where biomass is carried on the media for reduction of pollutants.

Clarification - Circular & Rectangular Collector Mechanisms

Walker - Model Type RS-S and RSP-S Series - Spiral Rake Clarifier

For greater flows and the resultant larger basins, higher torque capacities are required of the collector mechanism. A spur gear driven pier-supported collector is usually best applied in this class of service. Walker Process Type RS collectors are built around a center pier which supports the entire rotating portion of the machine plus half of the access bridge load. In addition to providing support, the pier resists the torque developed by the collector`s sludge plowing action.

Walker - Tapered Suction Header Type Clarifier

Suction header type mechanisms enable sludge to be "vacuumed" off the tank floor over the full length of each header. Tapered Suction Type Clarifier Mechanisms, Type SCTP or RSMTP provide rapid sludge removal with a low profile header that is sized to provide a relatively constant velocity along the length of the header and with orfices space and sized to provide a flowrate proportional to the tank floor area served.

SightWell - Model Type SW and SWP Series - Suction Pipe Clarifier

The Walker Process SightWell collector is designed to provide quick and uniform withdrawal of return and waste activated sludge from final settling tanks before the sludge becomes anaerobically degraded. Because modern plant designs incorporate high solids loadings in mixed liquor, rapid removal of oxygen-rich sludge is most important to ensure proper operation of the activated sludge process.

Clarification - Clarifier Drive Units

Walker - Clarifier Drive Units

Walker Process Equipment Spur Gear Drives are precision Class 6 gear assemblies (after heat treatment) and include a split spur gear ring that allows access to replaceable bearing race inserts. Housings are machined from cast iron to provide the highest level of precision and superior corrosion resistance for a very long, useful life. The drive and torque ratings are in full conformance and certifiable to the latest ANSI/AGMA standards.

Thickening - Gravity Thickening

Walker - Gravity Thickeners

The RS Thickener mechanism consists of two fabricated steel arms supported from a central rotating drive cage. The cage is suspended from an enclosed spur gear drive turntable unit which, in turn, is supported on the center pier. The driving unit consists of a special primary double reduction worm gear unit driven through a steel roller chain connectd to a gear motor with all-weather construction.