- Home

- Companies

- WAMGROUP S.p.A.

- Products

- Screw Conveyors & Feeders - Screw Conveyors

- Screw Conveyors & Feeders - Tubular Screw Conveyors

- Screw Conveyors & Feeders - Micro Batch Feeders

- Screw Conveyors & Feeders - Metering Feeders

- Screw Conveyors & Feeders - Live Bin Bottoms

- Mechanical Conveyors

- Butterfly Valves

- Screw Conveyors & Feeders

- Rotary Valves - Rotary Feeders

- Bulk Solids Dischargers

- Screens

- Dust Collectors

- Mechanical Conveyors

- Valves

- Clarifiers and Thickeners

- Grit Treatment Equipment

- Septage Receiving Stations

- Rotary Valves - Rotary Feeders

- Compactors

- Valves- Butterfly Valves

- Penstocks

- Valves- Slide Valves

- Trough Screw Conveyors

- Bulk Solids Dischargers- Bag Openers

- Bulk Solids Dischargers- Bin Activators

WAMGROUP S.p.A. products

Screw Conveyors & Feeders - Screw Conveyors

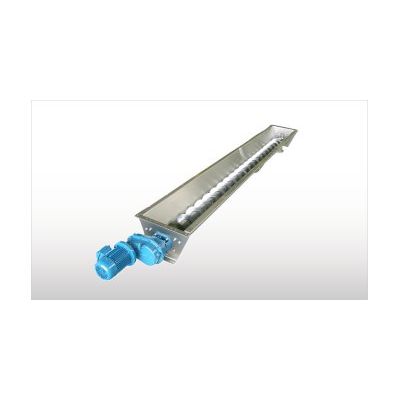

Wamgroup - Model CX - Stainless Steel Trough Screw Conveyors

The modular CX Trough Screw Conveyor system offers a variety of solutions for conveying or feeding powdery or granular materials. Designed for application in the food industry and in environmental technology, they are suitable for applications in which any contamination of the material handled has to be strictly avoided and where absolute cleanliness and perfect resistance to corrosion are required. CX Trough Screw Conveyors are also used in flour and animal feed milling, in plastics and chemicals, as well as in the pharmaceutical industry.

Wamgroup - Model CMC - Screw Conveyors for Fresh Concrete

CMC Screw Conveyors are used in the precast concrete industry to convey fresh concrete from the compulsory mixer to the moulds, as an alternative to belt conveyors which, unlike screw conveyors, bear the risk of segregation of fresh concrete. CMC-type Screw Conveyors are manufactured from carbon steel with a suitable surface finishing. They are made up of a U-shape trough with wear-resistant rubber drop bottom. CMC Screw Conveyors have an outlet spout at one trough end, an end plate at each trough end, helicoid screw flighting welded on a centre pipe with coupling bush at each end, two end bearing assemblies complete with shaft seal, and a bolted trough cover. Furthermore, CMC Screw Conveyors are equipped with a gear motor that suits the application. The inlet zone is equipped with adjustable mixing paddles.

Screw Conveyors & Feeders - Tubular Screw Conveyors

Wamgroup - Model CAO - Tubular Trough Screw Conveyors

The modular CAO Tubular Trough Screw Conveyor system is highly versatile offering numerous solutions for conveying powdery or granular materials. They are widely used all over the world in industries such as flour milling, animal feed milling. In general, CAO Tubular Screw Conveyors and Feeders are suitable for applications that require minimum material residue and maximum conservation of particle size of the material when handled.

WAM - Model TU - Tubular Screw Conveyors

The modular TU Tubular Screw Conveyor and Feeder system is highly versatile offering a variety of standard solutions for handling of powdery or granular materials. Different models of conveyors or feeders are available in applications such as concrete production (for fly-ash, filler dust, silica fume), premixed building materials (dry plasters, sand, cement, additives), glass processing (calcium carbonate, soda, sand, etc.), foundries (sand, bentonite), and many others.

Screw Conveyors & Feeders - Micro Batch Feeders

Wamgroup - Model MBF - Micro-Batch Feeders with Agitator

MBF Micro-Batch Feeders are particularly suitable for feeding poorly flowing powders and granular materials which tend to clog. A comprehensive modular system design ensures the right solution for virtually all user requirements. The MBF Micro-Batch Feeder for continuous volumetric feeding of powdery or granular materials consists of a steel-reinforced SINT engineering polymer body (optionally body entirely manufactured from stainless steel), a horizontally mounted rotating agitator tool, a feeder screw beneath the agitator tool, a feeder pipe enclosing the protruding feeder screw, one drive unit each for agitator and feeder screw. Tests on product flow and material stress were carried out to establish optimum body geometry. Agitator and feeder tool geometry and materials were tested, too, before choosing an optimal steel and SINT engineering polymer composite. On request, MBF series Micro-Batch Feeders are supplied in food-grade versions with both FDA and EN- approval.

Wamgroup - Model MBH - High Efficiency Micro-Batch Feeders

MBH is the most versatile and economic solution for high efficiency micro-batch feeding. It is available in 3 different versions (standard in 316 SS, with SINT engineering polymer chamber and feeder pipe and a version for Food applications with ATEX and EC 1935/2004 certification).

Wamgroup - Model FLEXFLO MBW - Micro Batch Feeders

MBW Micro-Batch Feeders are particularly suitable for feeding free or moderately flowing materials which do not tend to pack under pressure in a variety of industries, among which plastics processing, animal feed milling, as well as waste water and drinking water treatment. MBW Micro-Batch Feeders for continuous volumetric feeding of powdery or granular materials consist of a SINT engineering polymer FLEXFLO body with integrated feeder outlet pipe, a feeder screw and a drive unit.

Screw Conveyors & Feeders - Metering Feeders

Wamgroup - Model DCC - Loss In Weight Screw Feeders

DCC Loss-In-Weight Screw Feeders offer exceptional operating versatility due to highly precise metering performance and excellent user-friendliness. DCC Loss-In-Weight Screw Feeders consist of a micro-screw feeder inside a food-grade polymer body with stainless steel guards and feeder pipe and an optional electronically operated scale pan mounted on load cells.

Screw Conveyors & Feeders - Live Bin Bottoms

Wamgroup - Model MU - Live Bin Bottoms Feeder

MU Live Bin Bottoms are the ideal solution for discharging particularly difficult materials from polygonal hoppers or silos. Among others, they are used for extracting biological or industrial sludge, paper scrap, wood chippings, sawdust, as well as flour or bran in the flour milling industry.