- Home

- Companies

- Ward & Burke

- Products

Ward & Burke products

Packaged Pumping Stations

Response Group manufacture and install a range of Packaged Wastewater and Stormwater Pumping Stations. These stations incorporate submersible pump sets and are installed in precast concrete water-retaining structures with preformed sumps and pump stools. The main components are assembled under controlled factory conditions, are easily transportable and require only simple assembly on site. Single, dual or multiple pump arrangements are offered. A selection of operating control methods is available.

Dissolved Air Flotation

Response Group manufacture a range of Dissolved Air Flotation (DAF) units for the treatment of industrial and municipal wastewaters. DAF technology is the process by which suspended solids, oil, fat and grease (OFG) are separated from wastewater by dissolving pressurized air into a recycled stream of the liquid to be treated. Micro-bubbles interact with the solids causing them to float to the surface where they are skimmed and separated. DAF efficiency can be significantly improved by chemical pretreatment. High levels of BOD, COD and SS are removed in the process.

Tipping Buckets

Response Group manufactures Tipping Buckets suitable for a range of applications in the treatment of municipal wastewater and industrial effluent. The Tipping Bucket system provides an economic and efficient flushing system for stormwater, primary and secondary settlement tanks. The system can also be adapted to flush large diameter sewers designed to provide storage capacity. The Tipping Bucket is designed to fill with treated effluent on receipt of a signal from the control centre that the retention tank has emptied. The bucket or trough is designed as a finely balanced unit which as it reaches its capacity shifts from its centre of gravity and automatically tips its contents. The trough is supported on two specially designed bearings.

Rotating Half-Bridge Scraper

Response Group manufacture Rotating Half-Bridge Scrapers suitable for radial flow settlement tanks ranging in diameter from 6 metres to 30 metres. These Scrapers will collect primary or secondary sludges to a central hopper for removal and further treatment. Scraper blade design and blade tip speed of rotation are suited to the nature of the sludge to be collected and removed. Scraper blades can be fixed, trailing or hinged, with hinged design selected where reduced blade wear is desired. All scraper blades are removable and renewable. The basic scraper installation includes, bridge, centre steel tripod, end carriage, diffuser drum and underwater scraper assembly. The half-bridge scraper rotates about a central pivot and the outer end comprises the carriage which houses the bridge drive and wheel assemblies. Scrapers are positioned to create a spiral pattern which directs sludge towards a central collecting hopper.

Picket Fence Thickeners

Response Group manufacture Picket Fence Thickeners (PFTs) for the initial treatment of sludges in the wastewater industry, The Picket Fence Thickener is designed to promote agglomeration of the sludge particles and produce a post-clarifier sludge with higher solids concentration. The Picket Fence Thickener as the name suggests comprises a series of vertical posts supported on a structure that spans the consolidation tank. As the picket fence rotates slowly about the centre of the tank a series of vertical passageways are generated which permit the movement to the surface of separated water and micro-bubbles released from the floccs. The Picket Fence Thickener is a fixed bridge structure. The basic PFT includes the bridge structure, drive unit and motor, central drive shaft, diffuser box and picket fence assembly with scraper blades. In situations where desludging is likely to create odour nuisance a removable GRP roof can be supplied for odour containment prior to filtration.

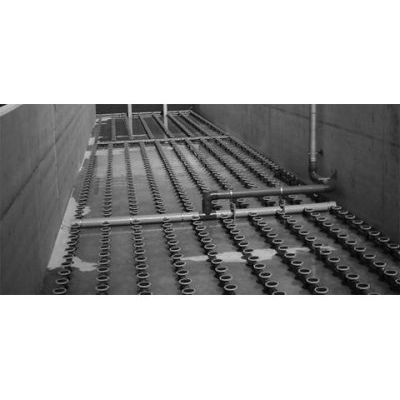

Diffused Aeration Systems

Response Group manufacture and install Fine Bubble Diffused Air (FBDA) Systems for the treatment of industrial and municipal wastewaters. FBDA systems supply oxygen to aerobic reactors by pumping air under pressure and releasing it in a stream of fine bubbles (< 1.5mm) in the mixed liquor. Circulation and mixing is achieved by the currents set up by the rising bubbles and oxygen transfer takes place between the air bubble and the surrounding liquid. The turbulence created at the reactor surface encourages enhanced oxygen transfer. Dry dust-free air is supplied from air blowers through a submerged conduit system to disc-shaped flexible EPDM membrane porous diffuser heads attached at regular intervals to the compressed air conduit. Oxygenation efficiencies of up to 2.5kg O2/kWh are achieved.

Grit and Grease Traps

Response Group manufacture grit and grease traps for small wastewater treatment package plants and large scale treatment plants. The large scale units are installed in an aerated rectangular channel (See Fig 1). Coarse bubble diffusers located near the base of the channel create a helical motion within the channel which causes the grit to settle to the bottom. Vertical slats located along the side of the channel cause the grease to separate and migrate to the quiescent zone on the opposite side. Grease is collected in this channel and is removed by a travelling bridge which is controlled on a timer.

Rotating Bar Interceptors

Response Group manufacture Rotating Bar Interceptors (RBIs) which operate as a coarse bar screen system to deny access to abnormally heavy objects which could cause damage to pumping installations, mechanically raked fine screens or other downstream wastewater treatment plant. The rotating bars, which revolve at approximately the same rate as effluent flow, direct the wastewater and normal solids through unhindered. The build-up of solids and the necessity for local removal is avoided. Various tube diameters and bar spacings are available to suit the most likely solids removal requirements.

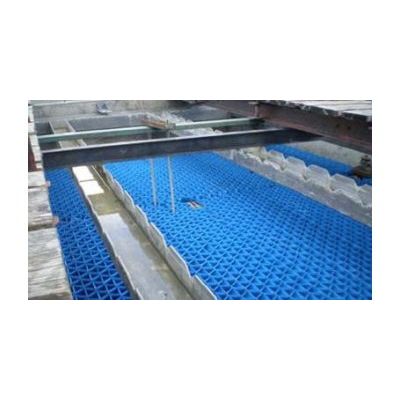

Lamellae Plates & Tube Settlers

Response Group provide lamellae plate and tube settling systems for water and wastewater treatment plant sedimentation tanks. Our lamellae plate and tube settlers can be provided as part of a new build or retrofitted to existing tanks to increase the efficiency of settlement processes. When retrofitted to existing tanks, the throughput of the plant can be increased by 200-400%.